| –

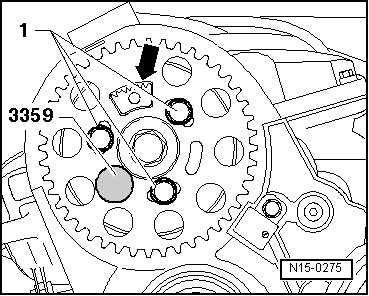

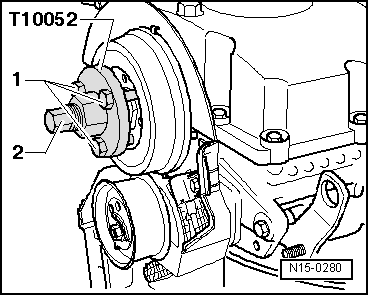

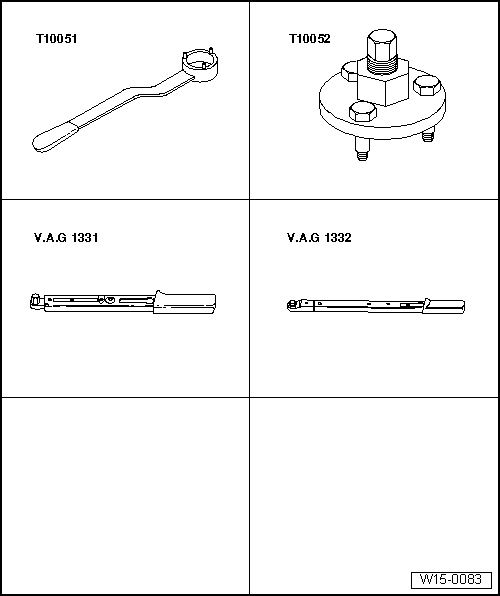

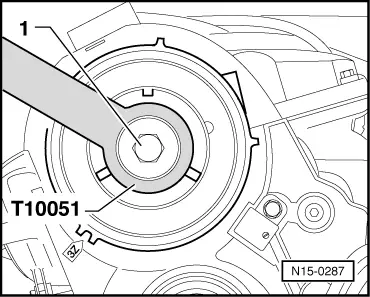

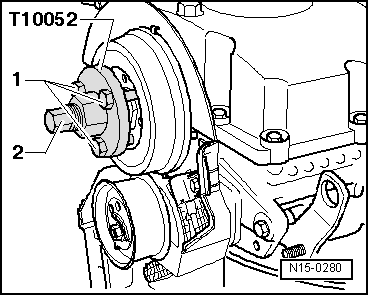

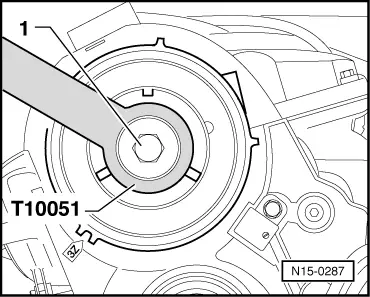

| Fit puller -T10052- and align it with holes in hub. |

| –

| Insert securing bolts -1- in hub. |

| –

| Apply tension to hub by evenly tightening puller central bolt -2- until hub releases from taper of camshaft. |

Note | When doing this, hold puller with 30 mm spanner. |

| –

| Remove hub from taper of camshaft. |

| –

| Remove cylinder head cover. |

| –

| Remove rocker arm shaft. |

Note | First loosen the outer and then both inner securing bolts, using diagonal sequence. |

| –

| First remove bearing caps 2 and 3. Loosen bearing caps 1 and 4 alternately and diagonally. |

Note | Bearing cap 4 is marked as bearing cap 5 |

Note | t

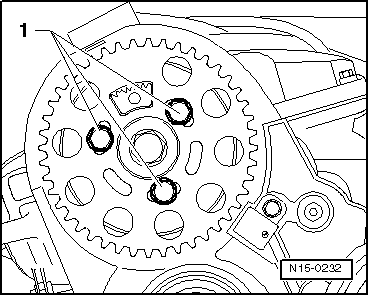

| When camshaft is installed, No. 1 cylinder cams must point upwards. |

| t

| Do not interchange used bearing shells (mark). |

| t

| When installing the camshaft, ensure proper seating of retaining lugs in bearing caps and cylinder head. |

| t

| Before installing bearing caps, ensure that cylinder head bolt washers are inserted in the cylinder head. |

| –

| Oil running surfaces of shell bearings. |

| –

| Tighten bearing caps 2 and 3 alternately and diagonally to 8 Nm + 1/4 turn (90°) further. |

| –

| Install bearing caps 1 and 4 and also tighten to 8 Nm + 1/4 turn (90°) (renew bolts). |

Note | t

| Bearing cap 4 is marked as bearing cap 5 |

| t

| Seal parting surfaces of bearing caps 1 and 4 with sealant -AMV 17400401- → Fig.. |

| t

| Bearing cap 4 must be flush with outer edge of cylinder head, otherwise leaks can occur at the tandem pump. |

| –

| Install rocker arm shaft, first tighten the inner and then the outer securing bolts evenly using diagonal sequence. Torque setting: 20 Nm + 1/4 turn (90°) further. |

|

|

|

Note

Note Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note