Polo Mk3

|

Dismantling and assembling engine

Removing, installing and tensioning toothed belts

|

|

|

Removing |

|

|

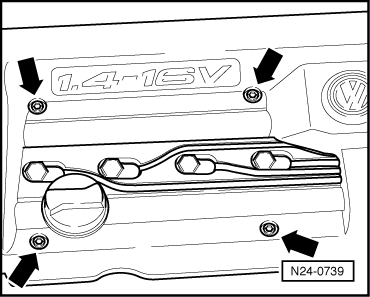

=> Repair group 24; Servicing injection; Dismantling and assembling air cleaner

|

|

|

|

|

|

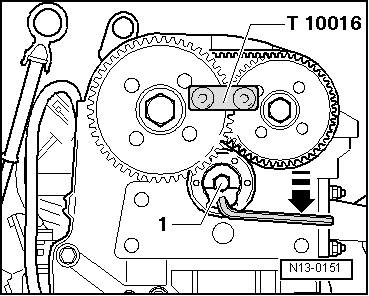

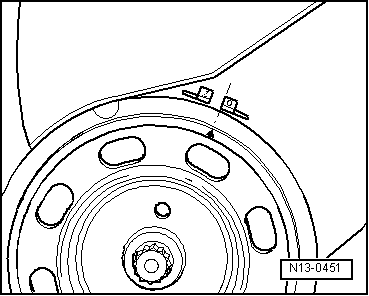

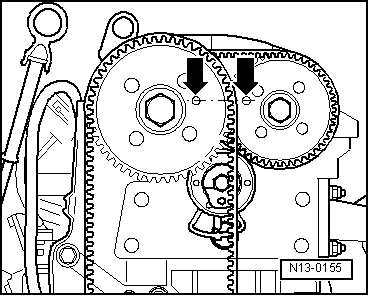

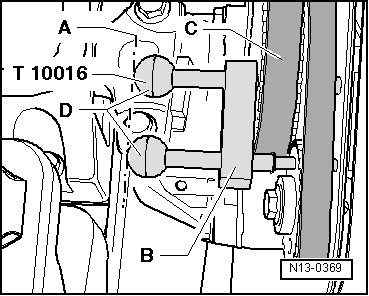

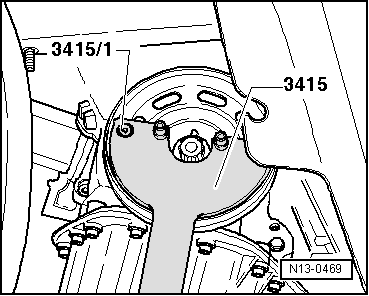

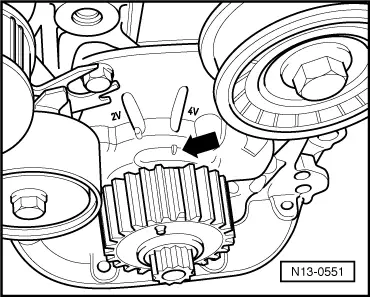

Note: If the locking pin holes are positioned to the outside on the toothed belt sprockets, the crankshaft must be turned one revolution further. Fix both camshaft sprockets with camshaft locking device T 10016 as follows: |

|

|

Note: Both locking pins are inserted correctly when the ends -D- align with line -A-.

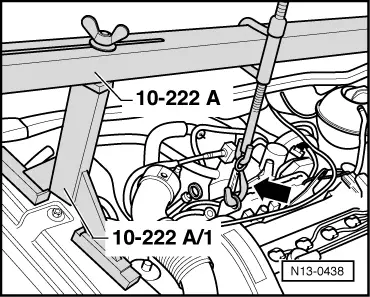

The engine must be lowered slightly as follows to enable the crankshaft sprocket to be removed: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

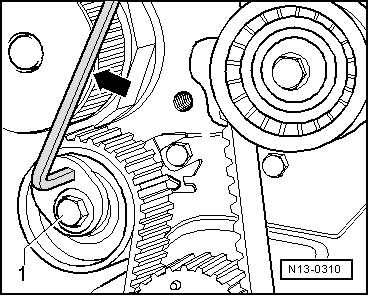

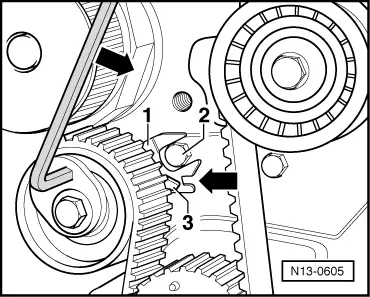

Removing main drive toothed belt:

Removing coupling drive toothed belt: |

|

|

|

Work sequence

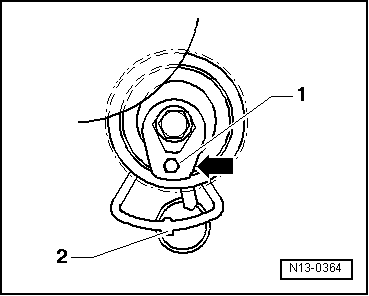

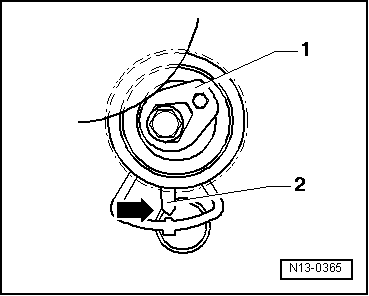

Install coupling drive tensioning roller as follows: |

|

|

|

|

|

Note: The tool must secure camshaft against turning until the main drive toothed belt is fitted.

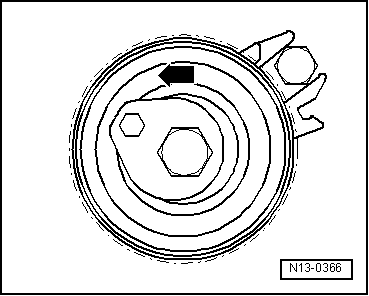

If tensioning roller was removed beforehand, install tensioning roller as follows: |

|

|

|

|

|

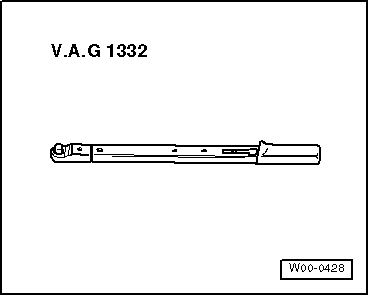

Tightening torques |

|

|

|

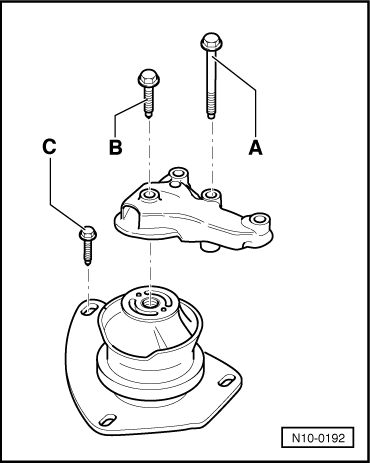

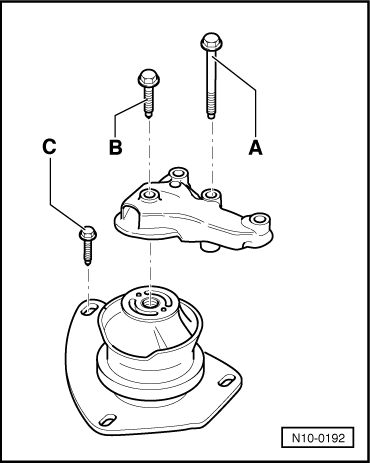

Note: The assembly mounting securing bolts are stretch bolts and must be replaced. → Engine mounting A = 40 Nm + 1/4 turn (90°) further

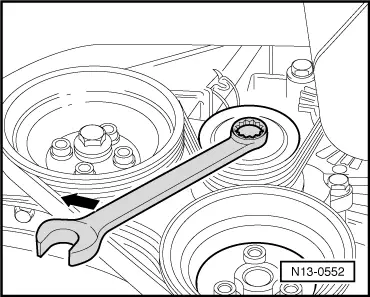

Note: When installing the ribbed belt ensure that it sits correctly in the pulleys.

=> Repair group 01; Fault memory; Interrogating and erasing fault memory of engine control unit |