Polo Mk3

|

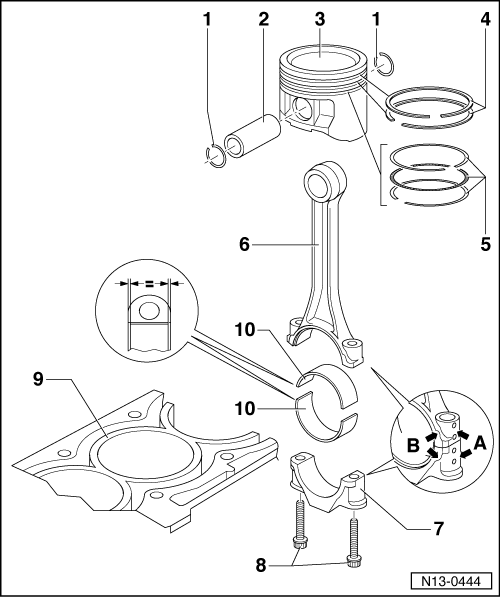

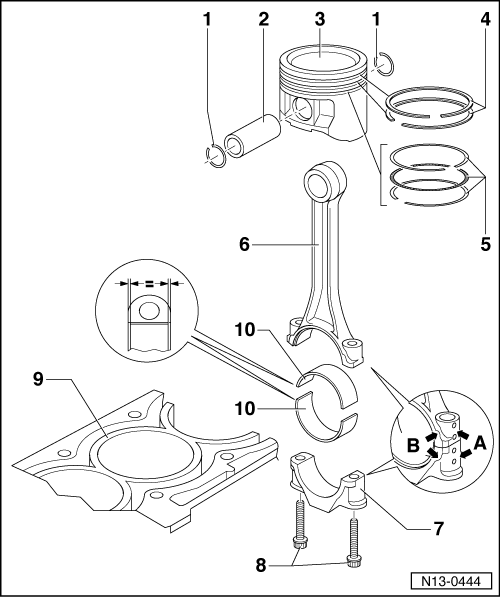

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

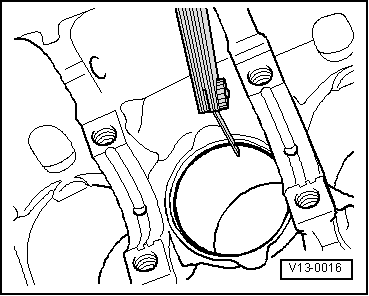

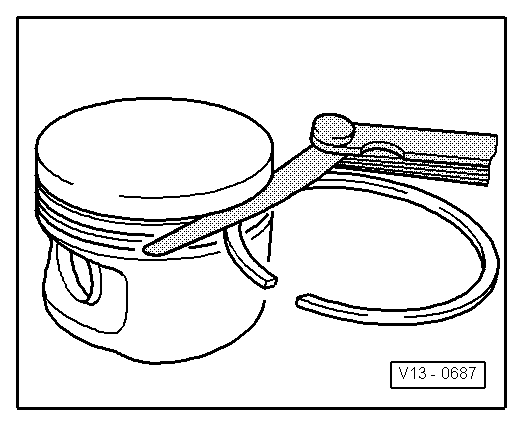

→ Fig. 2 Checking ring to groove clearance Clean groove before check.

| |||||||||||||

|

|

|

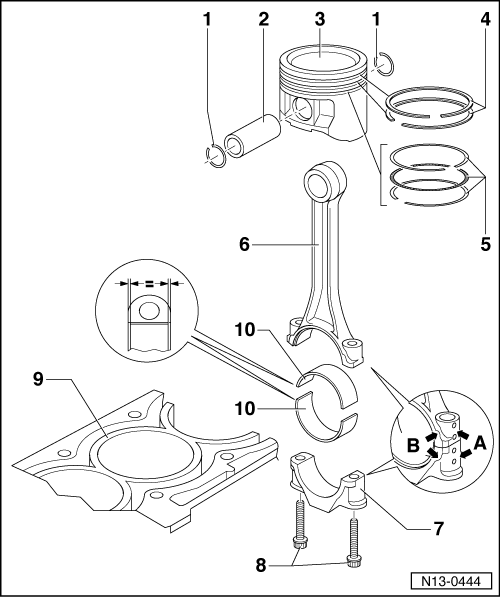

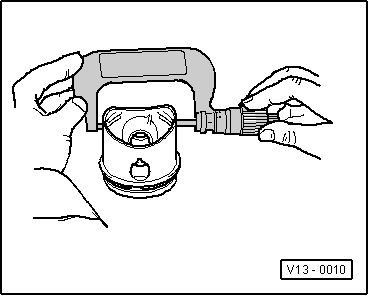

→ Fig. 3 Checking piston Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

|

|

|

|

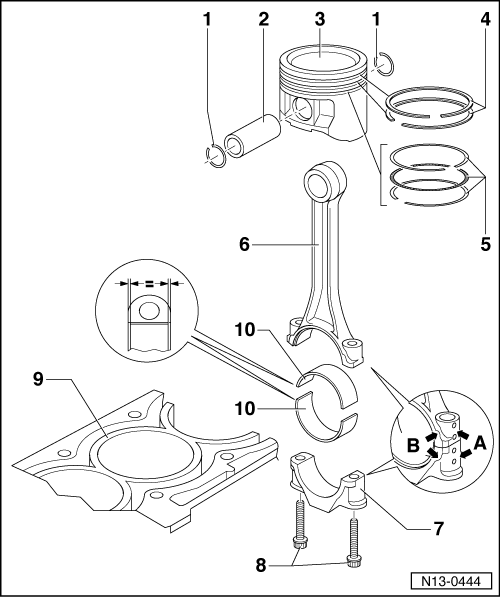

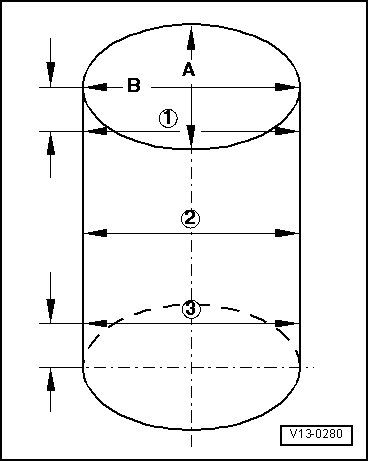

→ Fig. 4 Checking cylinder bores Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Note: Measuring the cylinder bores must not be done when the cylinder block is mounted on a repair stand with adapter bracket VW 540, as incorrect measurements would then be possible. |

|

|

|

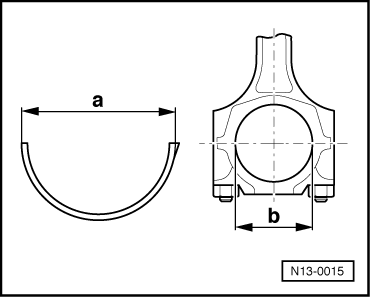

→ Fig. 5 Measuring bearing shell pretension Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

The bearing shell pretension is calculated as follows:

Bearing shell dimension -a- Minimum dimension: 1.5 mm If the pretension is not achieved:

|