Polo Mk3

|

Removing and installing parts of fuel supply system

Checking fuel pump

|

|

|

|

|

|

Test conditions

|

|

|

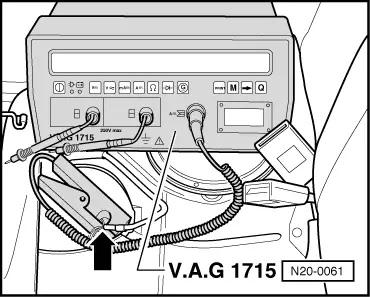

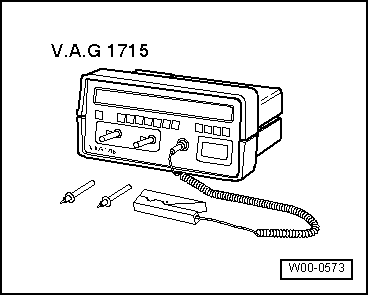

Checking function and voltage supply Note: Check whether a coded radio is installed as during the forthcoming work sequences the battery earth strap must be disconnected. Obtain radio code first if necessary.

If the fuel pump does not run: |

|

|

Fuel pump runs: |

|

|

=> Current flow diagrams, Electrical fault finding and Fitting locations Fuel pump does not run:

|

|

|

LED does not light up:

LED lights up (voltage supply OK.):

If not open circuit can be found:

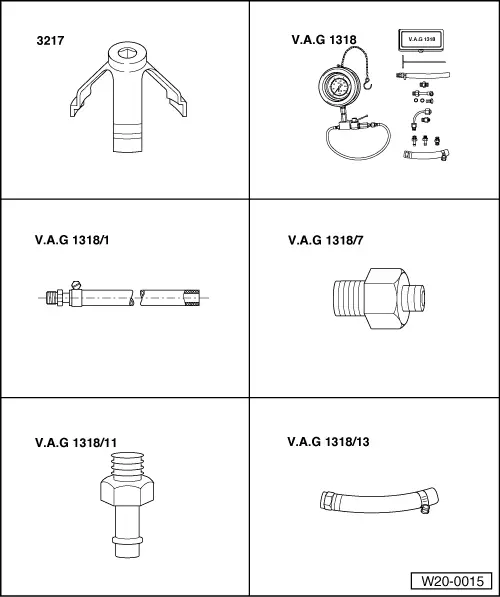

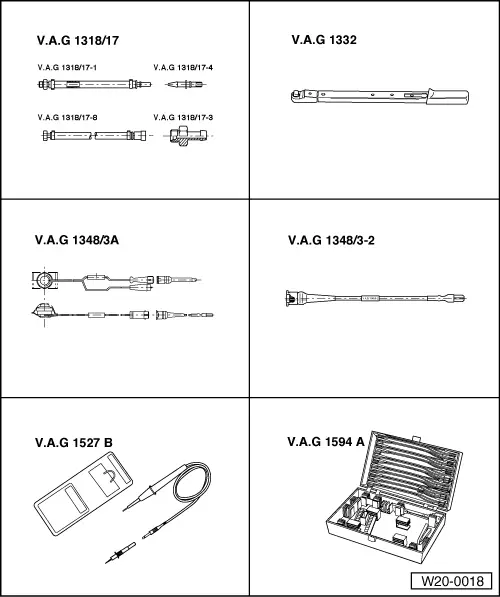

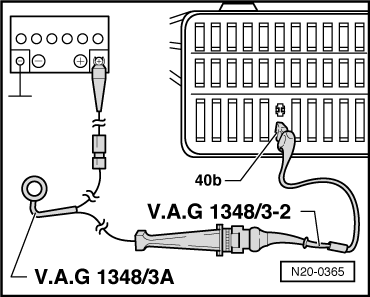

Checking delivery rate Test conditions

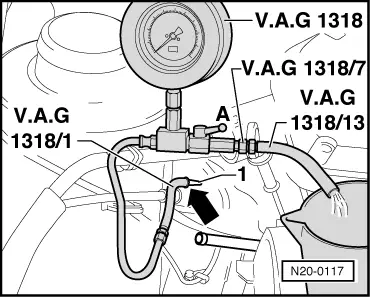

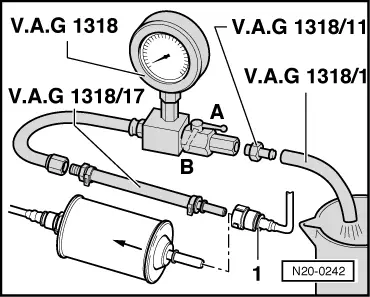

Test sequence

Warning!

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

|

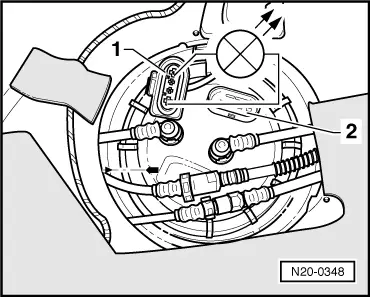

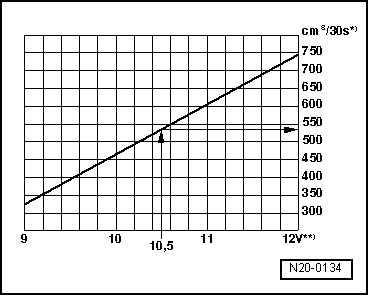

*) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stopped and pump running (approx. 2 volts less than battery voltage). Example: During the test, a voltage of 12.5 volts is measured at the battery. As the voltage at the pump is approx. 2 volts less than the battery voltage, this will equate to a minimum delivery of 540 cm3/30 s. If the minimum delivery rate is not attained:

|

|

|

If the minimum delivery rate is now attained:

If the minimum delivery rate is again not attained:

Only when up to now no fault has been detected:

If the delivery rate has been attained but nevertheless you suspect a fuel supply system fault (e.g. intermittent failure of fuel supply system):

|