Polo Mk3

|

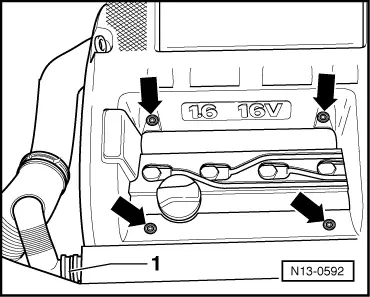

Removing and installing cylinder head

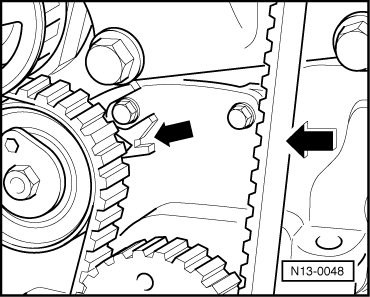

Checking semi-automatic toothed belt tensioning roller

|

|

|

=> Repair group 24; Servicing injection; Dismantling and assembling air cleaner

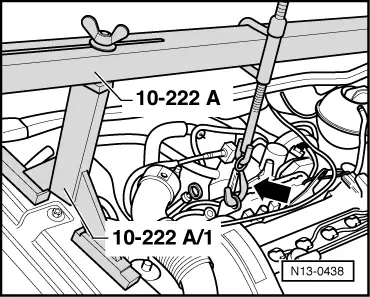

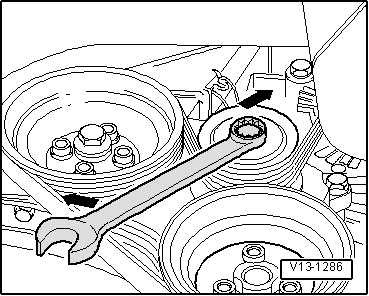

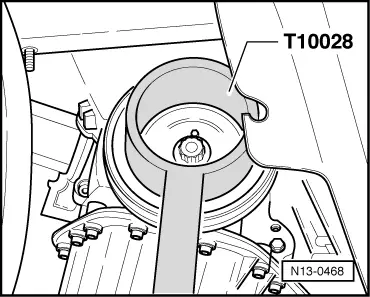

The engine must be lowered slightly as follows to enable the crankshaft sprocket to be removed: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If tensioning roller does not return to initial position:

|

|

|

|

Checking coupling drive tensioning roller:

If tensioning roller does not return to initial position:

If both tensioning rollers are OK:

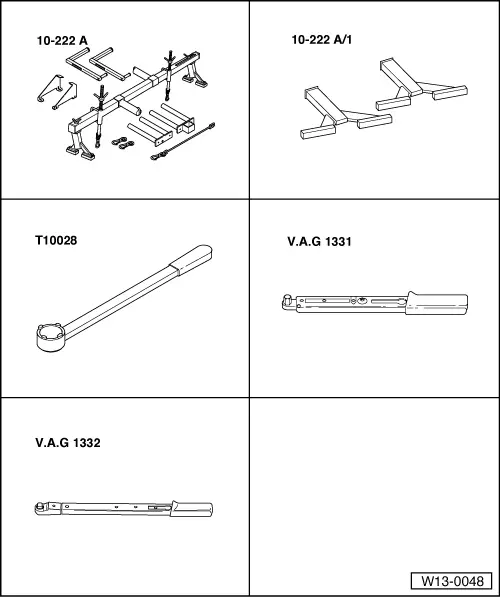

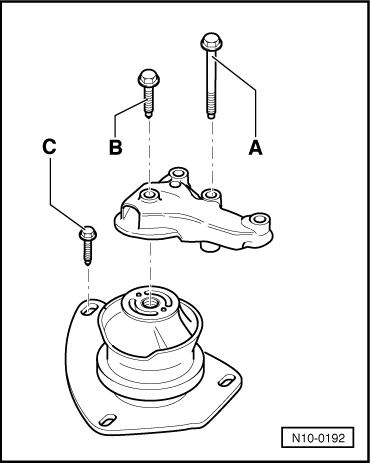

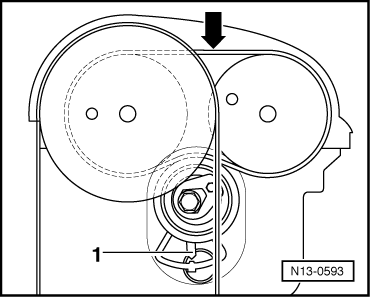

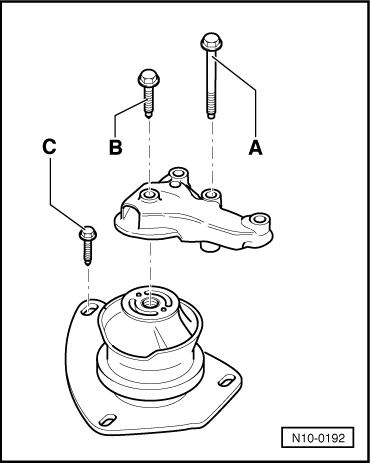

Tightening torques Note: The assembly mounting securing bolts are stretch bolts and must be replaced. |

|

|

|

→ Engine mounting A = 40 Nm + 1/4 turn (90°) further

Note: When installing the ribbed belt ensure that it sits correctly in the pulleys.

|