Polo Mk3

|

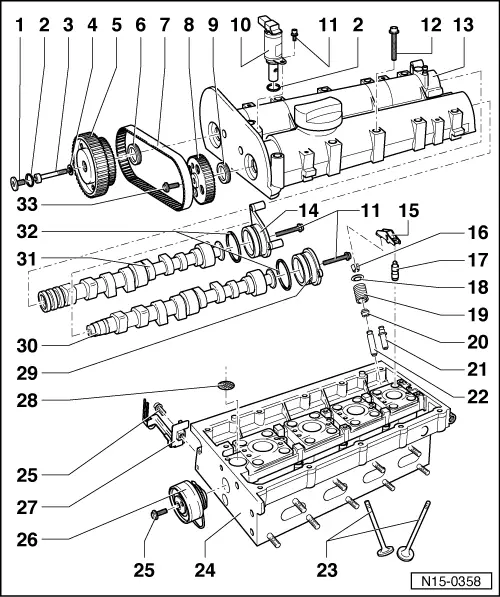

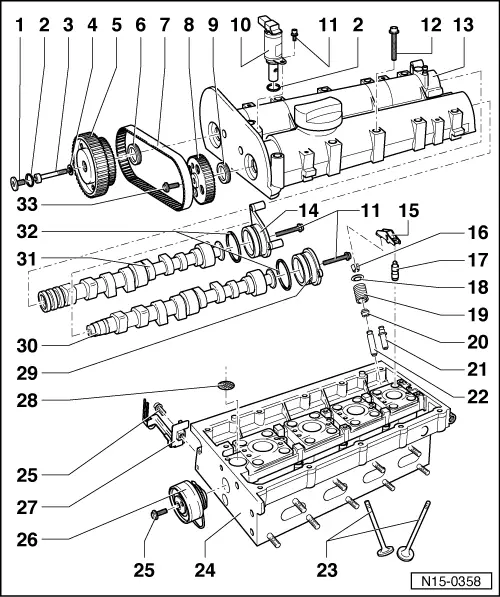

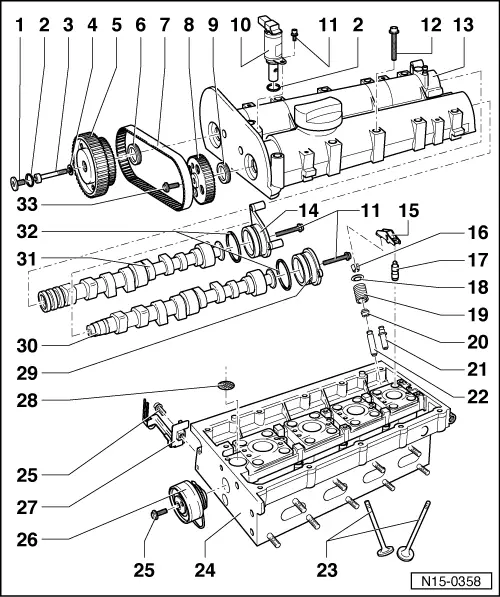

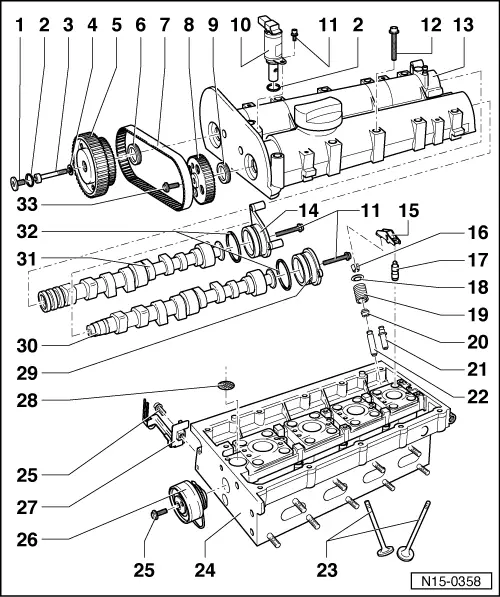

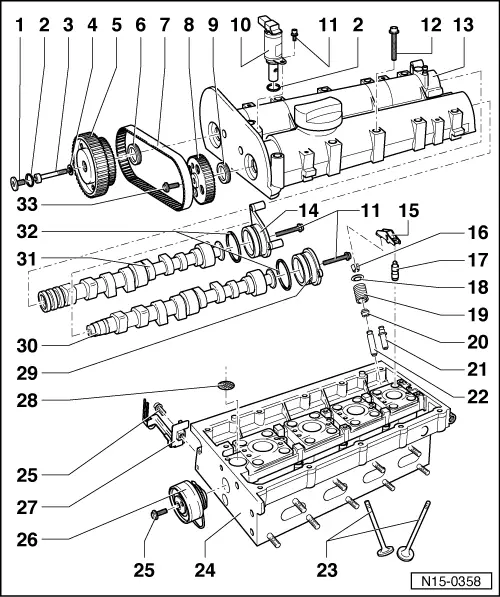

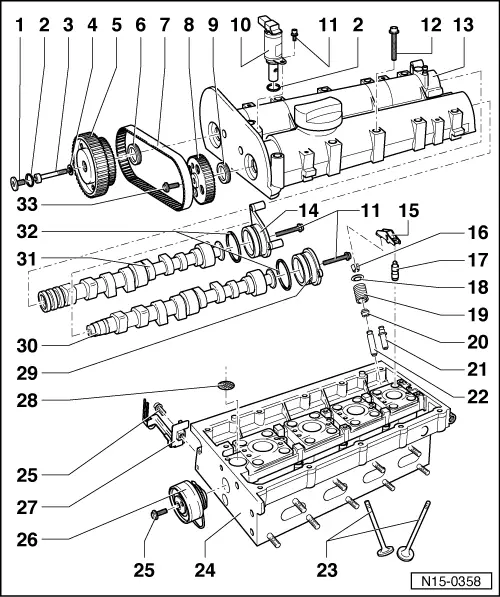

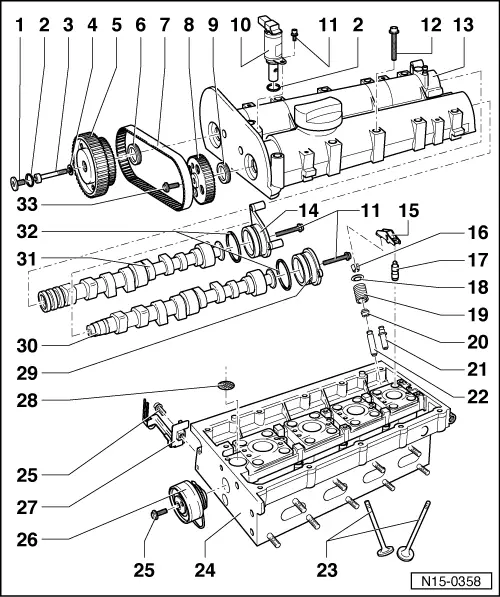

Servicing valve gear

Servicing valve gear

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

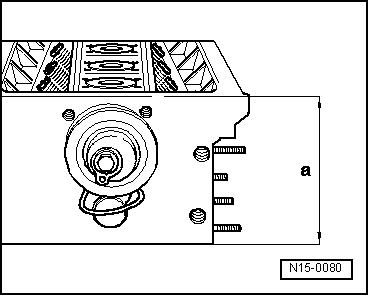

→ Fig. 1 Reworking cylinder head sealing surface Cylinder head reworking dimension: Note: When the sealing surface has been reworked, the valves must be set deeper by the same amount (rework valve seat inserts), otherwise valves will contact pistons. Ensure when doing this that the permissible minimum dimension is maintained => Page 15-58 . |

|

|||||||||||||||||||||

|

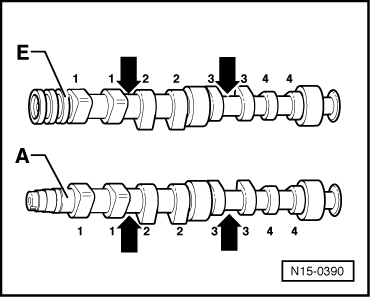

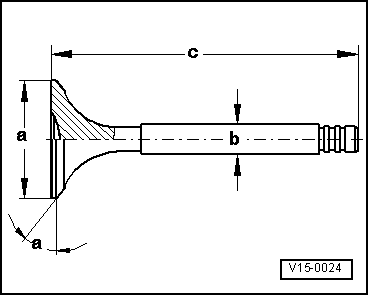

→ Fig. 4 Valve dimensions Note: Valves must not be reworked. Only lapping-in is permitted.

| |||||||||||||||||||||