Polo Mk3

|

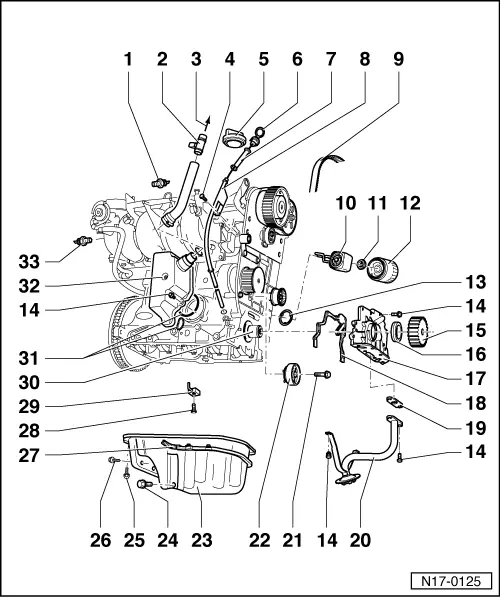

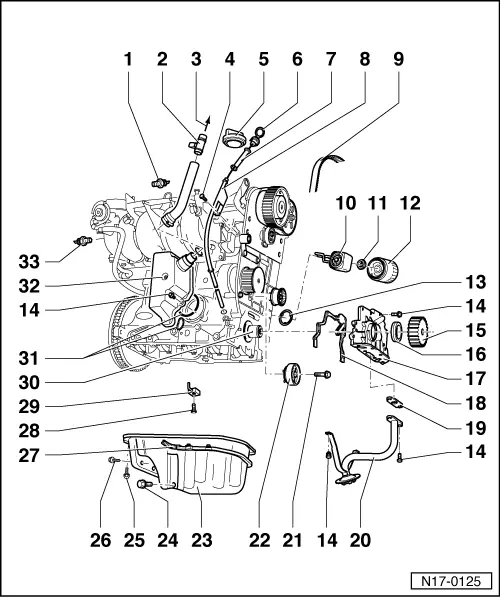

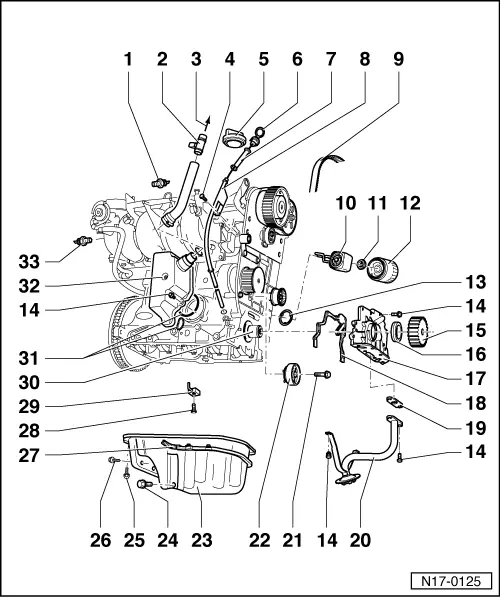

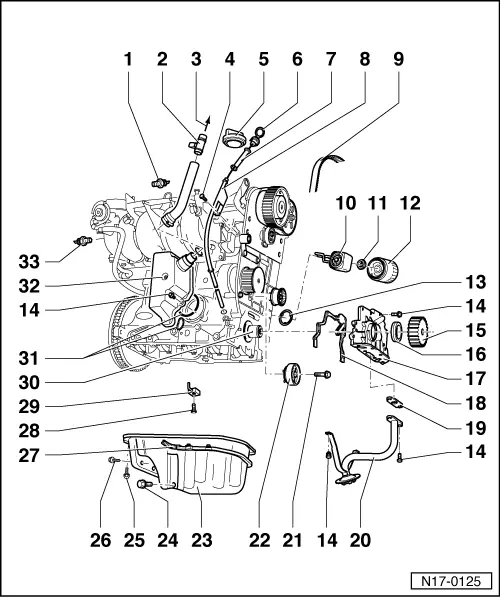

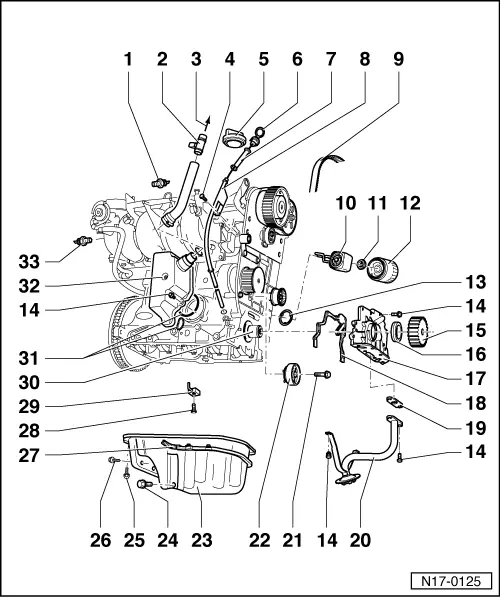

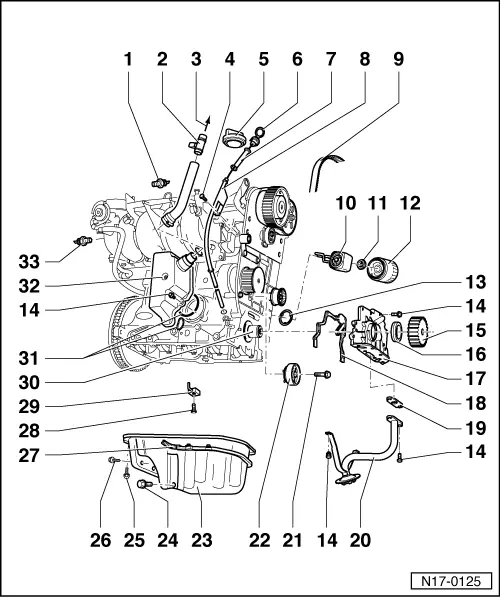

Removing and installing parts of the lubrication system

Removing and installing parts of the lubrication system

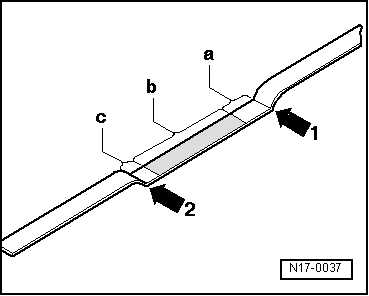

Note: The oil level must not be above the max. mark - danger of damaging catalyst! Marks , Fig. 1 . Checking oil pressure => Page 17-17 Oil system capacity1): with oil filter 3.2 ltr. 1) Up-to-date figures: => Exhaust emissions test binder Engine oil specifications: Note: Engines are filled at the factory with oil meeting VW standard 503 00. This engine oil is matched to long service intervals. However, you can also use the engine oils listed below. Use engine oil to VW standard 500 00, 501 01 or 502 00. Only in exceptional cases: Multi-grade oils corresponding to API-SF or SG. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|