-

‒ →

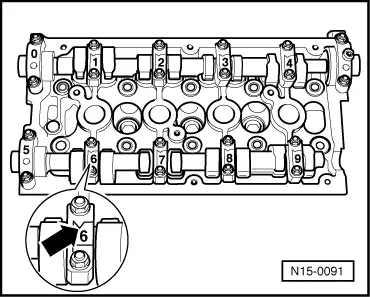

Tighten bearing caps 2 and 4 alternately and diagonally and then tighten to

6 Nm.

-

‒ Lightly coat contact surface of bearing cap 0 and distributor securing cap with sealant AMV 174 004 01.

-

‒ Install bearing caps 0, 1 and 3 and also the distributor securing cap and also tighten to

6 Nm.

When doing this insert distributor for centralizing securing cap.

-

‒ Turn all nuts by 1/4 turn (90 °) further.

Exhaust camshaft

-

‒ Tighten bearing caps 7 and 9 alternately and

diagonally and then tighten to

6 Nm.

-

‒ Coat bearing cap 5 seating areas lightly with sealant AMV 174 004 01.

-

‒ Install bearing caps 5, 6 and 8 and also tighten to

6 Nm.

-

‒ Turn all nuts by 1/4 turn (90 °) further.

-

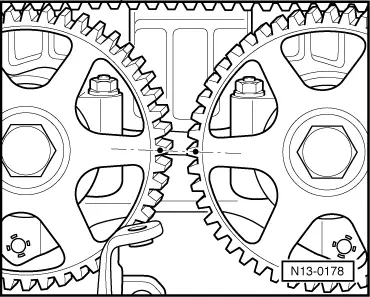

‒ Install camshaft sprockets.

-

‒ Hold the respective camshaft sprocket with counter-hold tool 3036 and tighten to

20 Nm

and then turn bolt

1/4 turn (90 °) further.

The rest of the assembly is basically a reverse of the dismantling sequence.

Installing toothed belt and adjusting timing => Page 13-12

.

Note:

When new tappets have been installed the engine must not be started for about 30 minutes. Hydraulic compensation elements must settle (otherwise valves will strike pistons).

|