Polo Mk3

|

Removing and installing engine

Notes on removing

=> General body repairs, Repair group 63; Front bumper, removing and installing front bumper

=> General body repairs; Repair group 50; Body front; lock carrier service position

|

|

|

=> Repair group 24; Servicing injection; Dismantling and assembling air cleaner |

|

|

Warning!

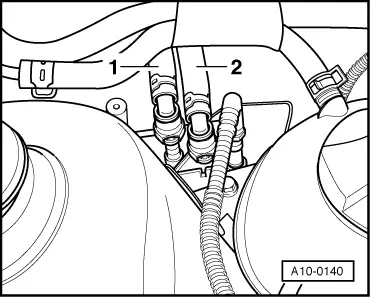

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection.

Vehicles with manual gearbox

=> 5-Speed manual gearbox 02K; Repair group 34; Servicing selector mechanism Vehicles with automatic gearbox

Continuation for all vehicles

=> General body repairs; Repair group 50; Front body; Removing insulation tray

Vehicles with air conditioner

Vehicles with manual gearbox

=> 5-Speed manual gearbox 02K; Repair group 30; Servicing clutch control Note: Clutch pedal must not be depressed. Continuation for all vehicles

|

|

|

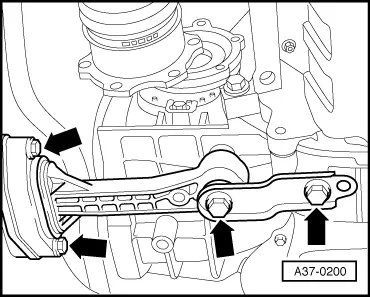

=> Running gear; Repair group 40; Removing and installing drive shaft |

|

|

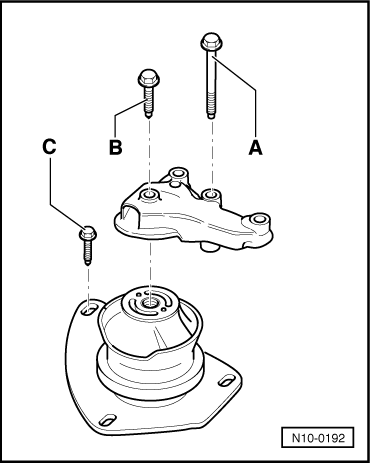

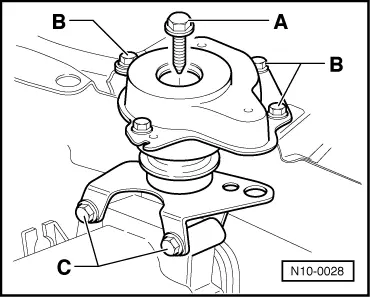

Pulley end:

Flywheel end: Warning!

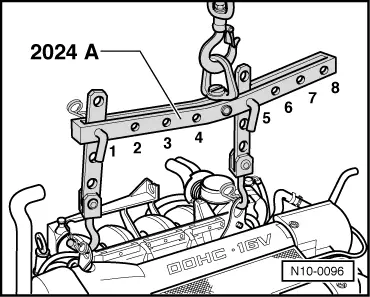

The hooks and locating pins must be secured with locking pins. Notes:

|

|

|

|

|

|

Turn assembly slightly to left (engine forwards, gearbox rearwards) and lift engine carefully out forwards. Note: When the assembly is lifted off, it must be carefully guided to prevent damage to the bodywork. |