Polo Mk3

|

|

|

|

|

|

Test sequence

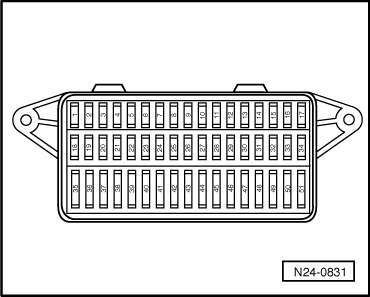

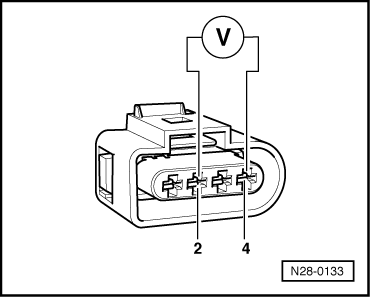

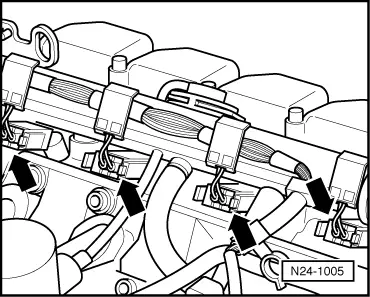

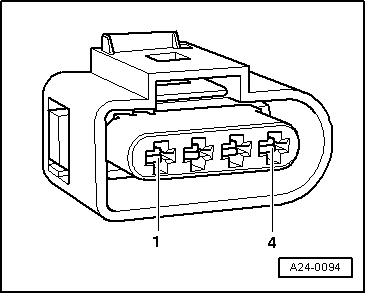

Checking voltage supply |

|

|

If no voltage is present: |

|

|

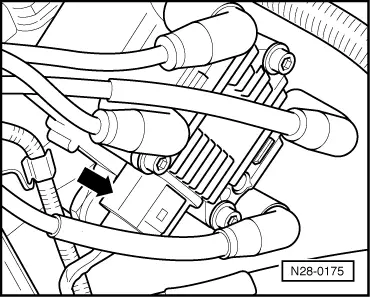

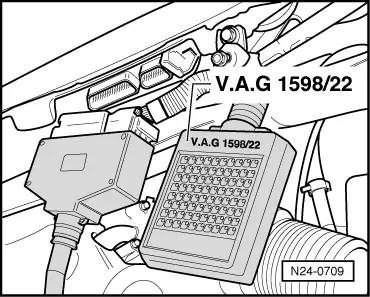

Checking activation Warning!

During the following test do not touch the terminals of the ignition transformer or test cables. |

|

|

|

|

|

If the LED flickers and there is voltage between contacts 2 + 4: The LED does not flicker:

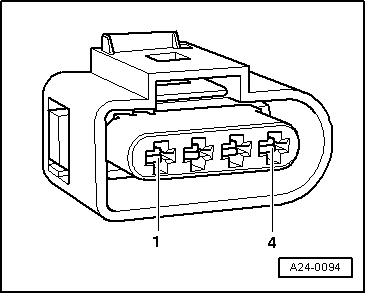

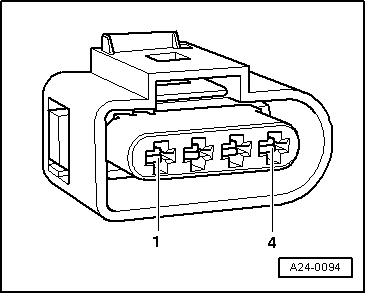

Checking wiring |

|

|

|

|

|

If no wiring fault is detected and voltage was present between contacts 2+4:

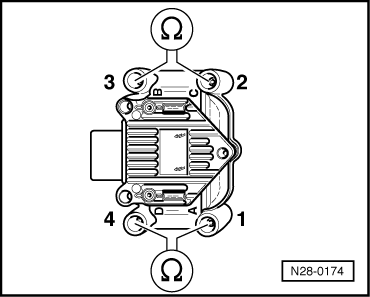

Checking secondary resistance |

|

|

If the specifications are not attained: |