Polo Mk3

|

Checking components

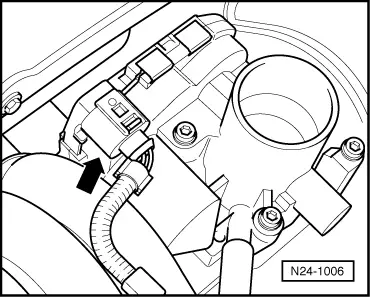

Checking throttle valve control part

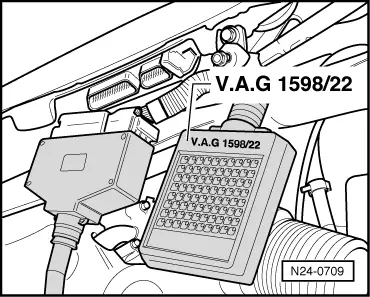

Components of throttle valve control part (J338): Note: If the throttle valve control part is replaced, the new control part must without fail be adapted to the engine control unit . Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Check conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

||

Notes:

If the displays do not indicate as described: |

|

|

|

|

|

If the specification is not obtained:

If the specification is obtained:

If the voltage supply and wiring is OK:

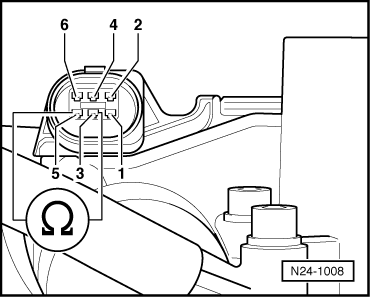

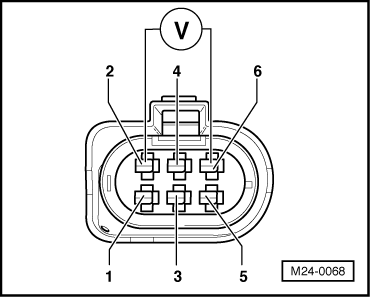

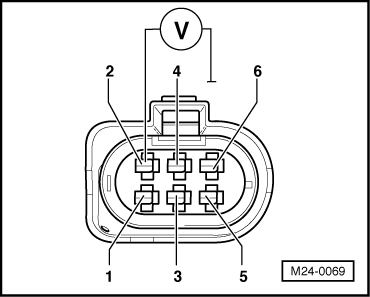

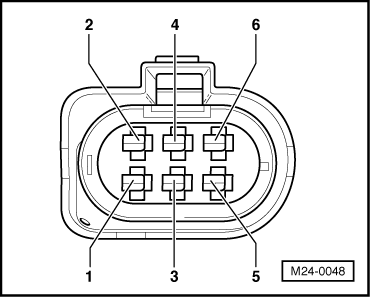

Checking voltage supply and wiring to control unit |

|

|

|

Test conditions

Test sequence

|

|

|

If the specifications are not attained: |

|

|

|

|

|

If no fault is detected in the wiring:

|