Polo Mk3

|

Servicing injection system

Checking injectors

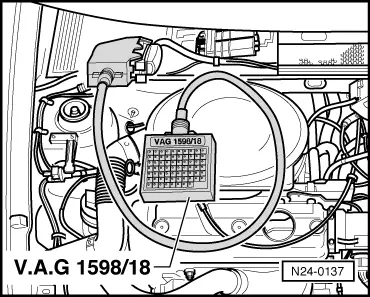

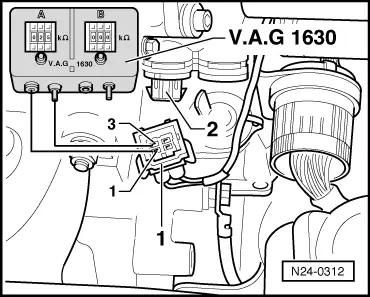

Checking activation Special tools, testers, measuring instruments and auxiliary items required

Check conditions

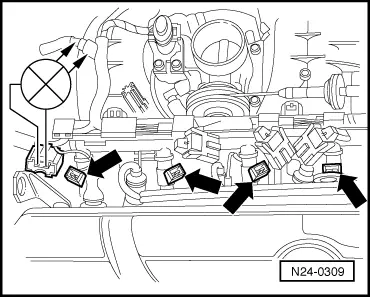

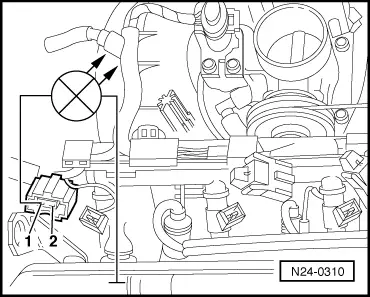

Test sequence

|

|

|

The LED does not flicker on any cylinder: |

|

|

If the LED does not light up:

The LED flickers on one or several cylinders: |

|

|

|

|

|

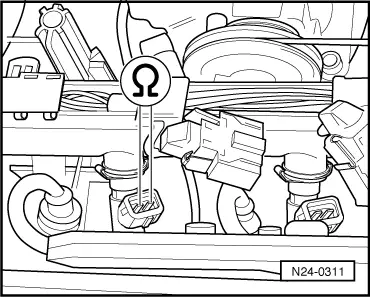

Checking resistance of injectors with wiring

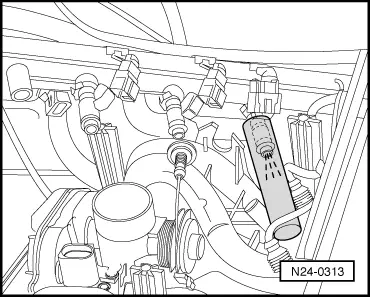

Checking spray pattern and for leaks Special tools, testers, measuring instruments and auxiliary items required

Test sequence

|

|

|

|

|

|

Note: When installing the injectors ensure that the O rings are not damaged. |