Polo Mk3

|

|

|

|

|

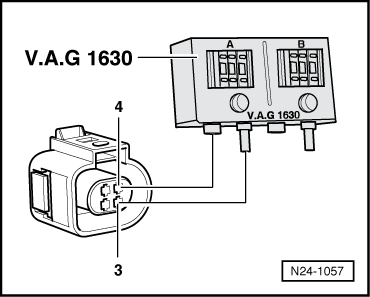

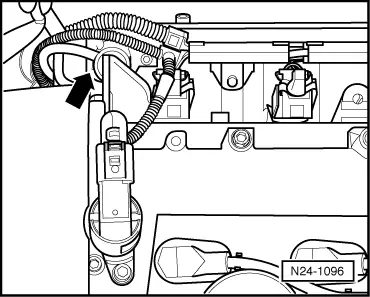

Checking activation and voltage supply

|

|

|

|

|

|

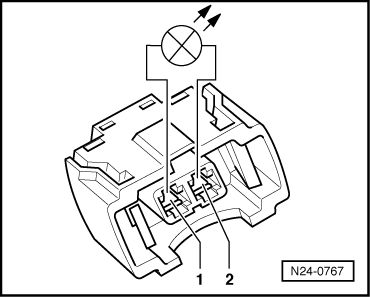

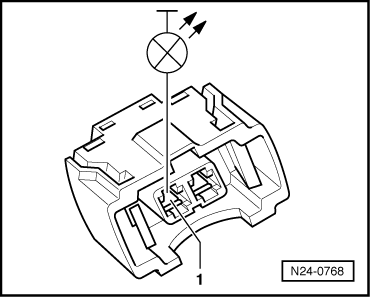

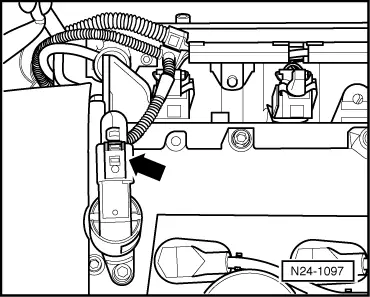

If the LED flickers on one or several cylinders: |

|

|

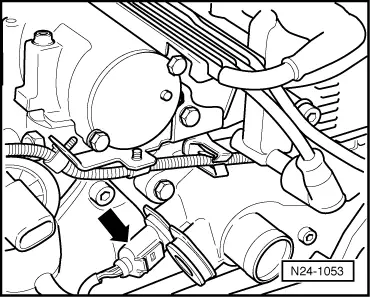

If the LED does not light up:

|

|

|

|

If the LED does not light up on one or several cylinders:

|

|

|

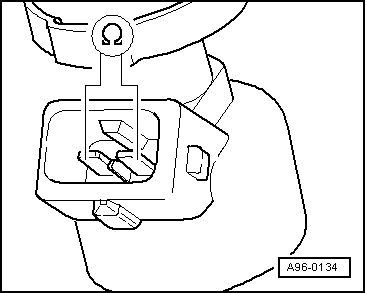

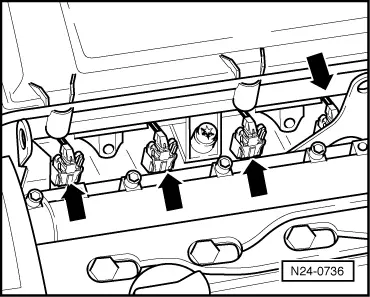

Note: The resistance figures are valid for approx. 20 °C. At higher temperatures the resistance figures will increase. If the specification is not attained: Perform installation of injectors in reverse order. When doing this note the following:

If the resistances are OK and no faults can be detected in the wiring:

|

|

|

|

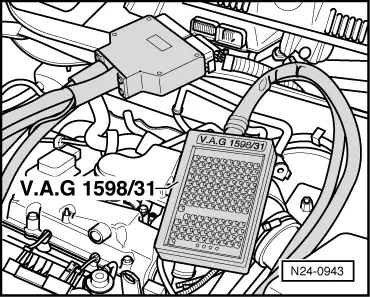

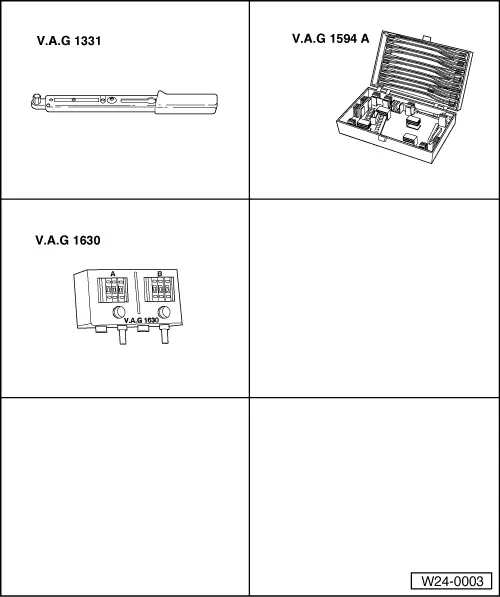

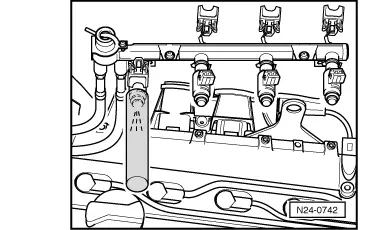

Checking spray pattern and for leaks Special tools, workshop equipment, test and measuring appliances and auxiliary items required

Test conditions

|

|

|

|

Test sequence |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If the fuel loss is greater:

Perform installation of injectors in reverse order. When doing this note the following:

|