Polo Mk3

|

Servicing front suspension

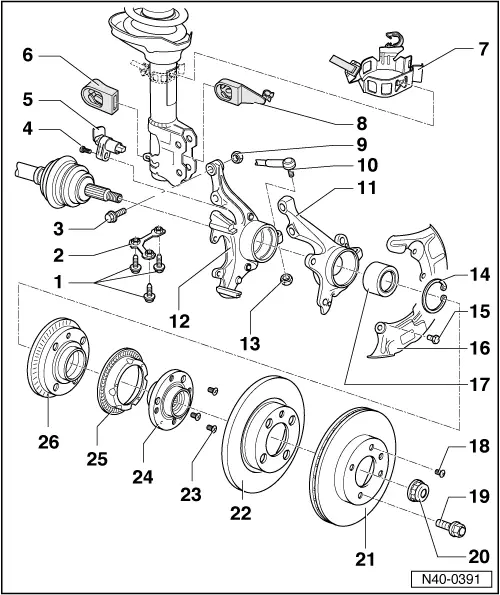

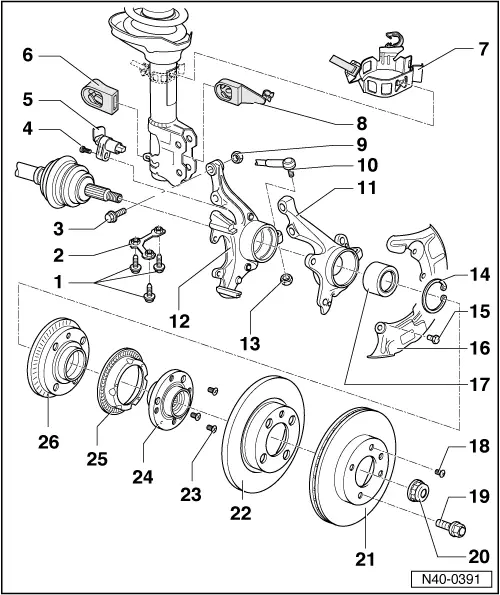

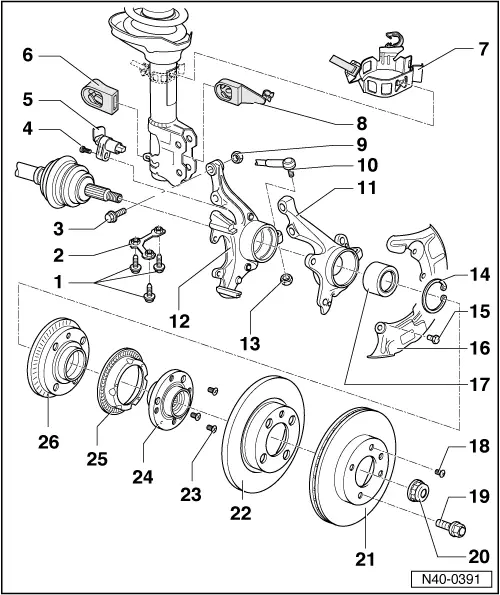

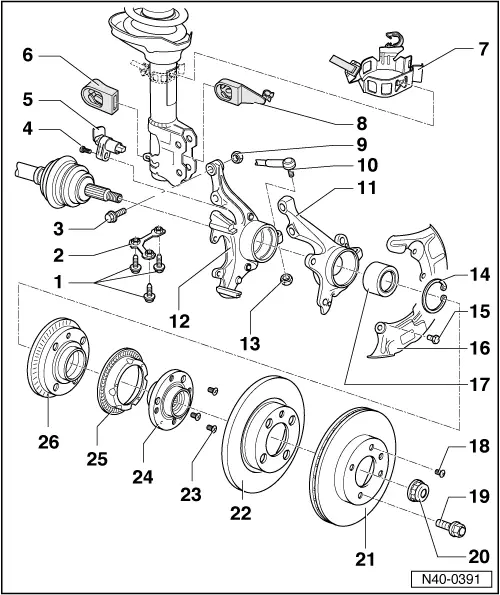

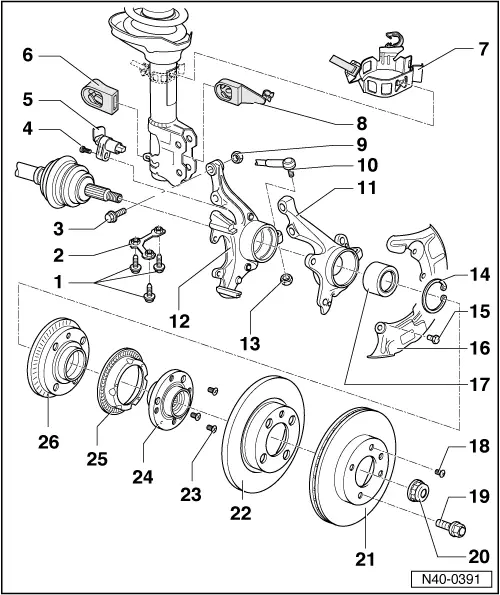

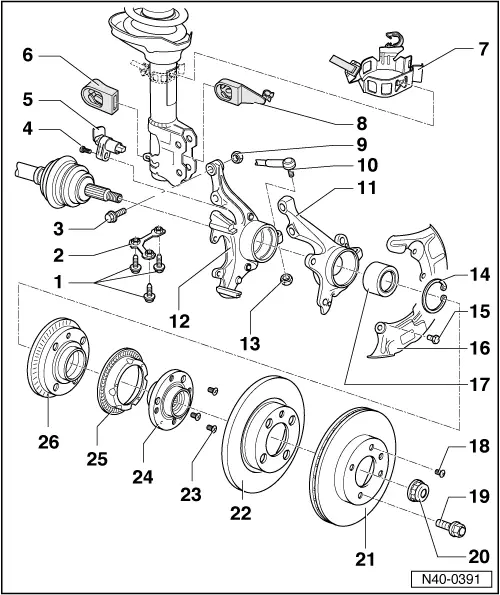

II - Assembly overview wheel bearing, suspension strut

|

|

|

|

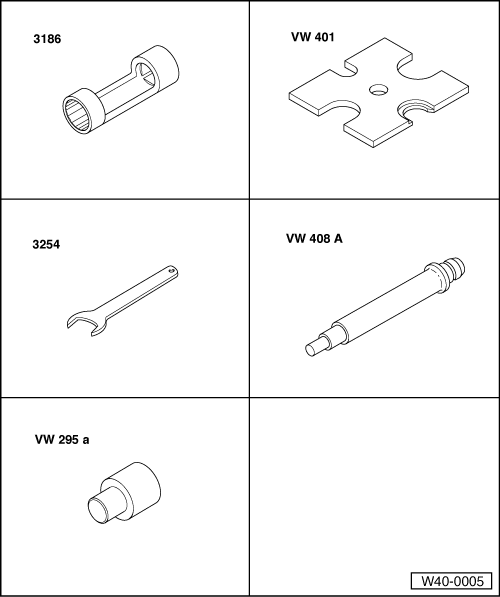

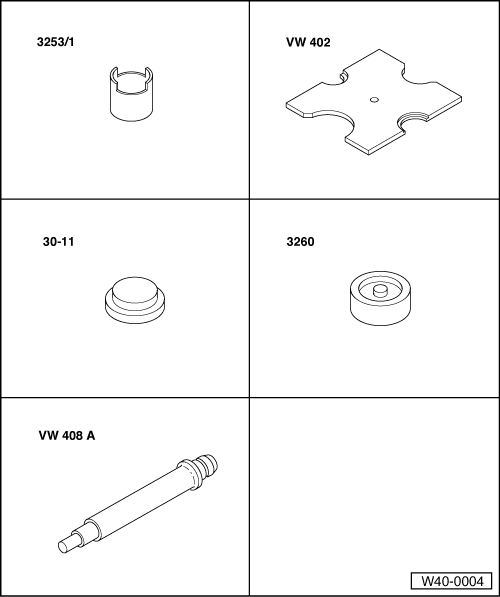

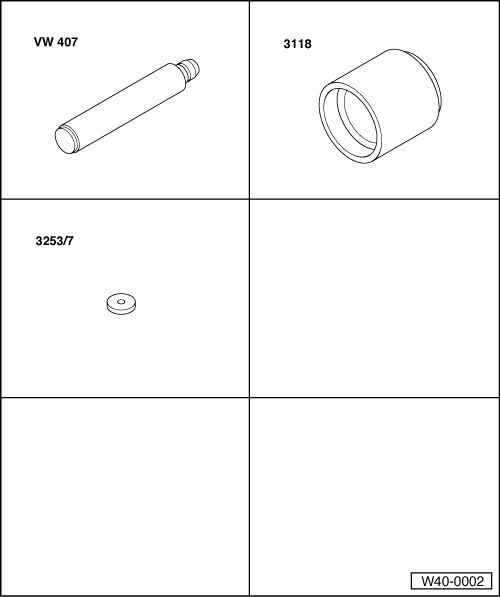

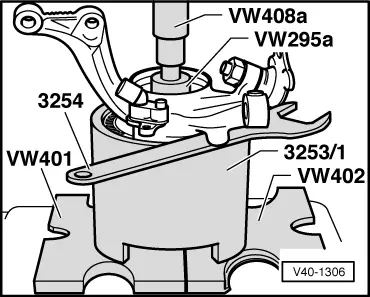

Special tools and workshop equipment required

|

|

|

|

Special tools and workshop equipment required

|

|

|

|

Special tools and workshop equipment required

|

|

|

|

Notes:

|

|

|

|

|

|||||||||||

| |||||||||||

|

|||||||||

| |||||||||

|

|

|

|

|

|

|

|

|

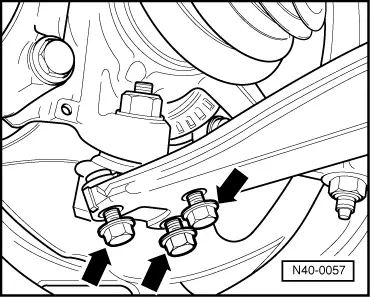

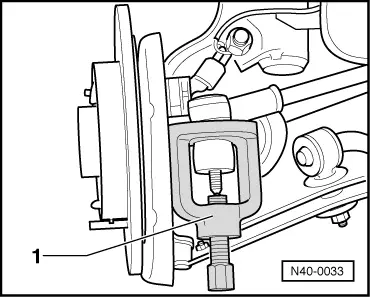

→ Fig.1 Separating ball joint/wishbone connection

|

|

|

|

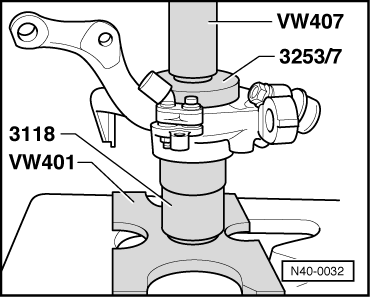

→ Fig.2 Pressing wheel hub out of wheel bearing housing |

|

|

|

→ Fig.3 Pulling bearing race out of hub Remove speed sensor rotor if fitted (on vehicles with ABS). Only use puller with leg clamp e.g. Kukko 204-2 (commercial type). |

|

|

|

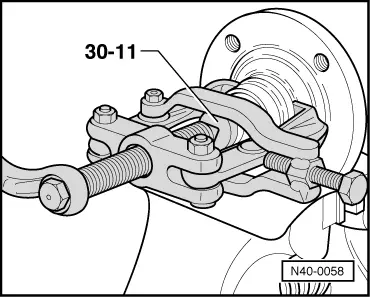

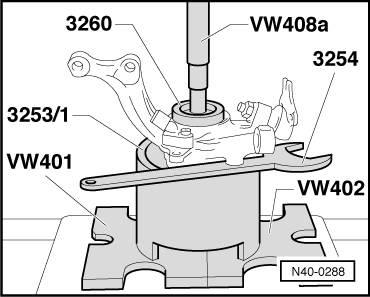

→ Fig.4 Pressing wheel bearing out of wheel bearing housing Fist remove securing ring. |

|

|

|

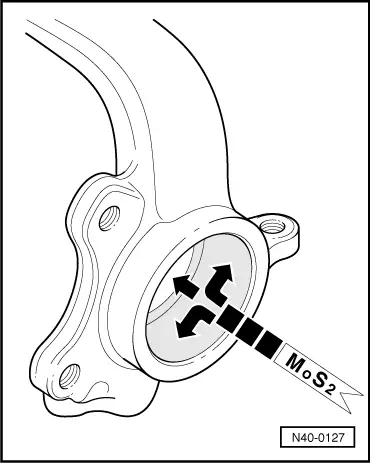

→ Fig.5 Coating hole surface with Molykote grease Use grease sachet from repair set. |

|

|

|

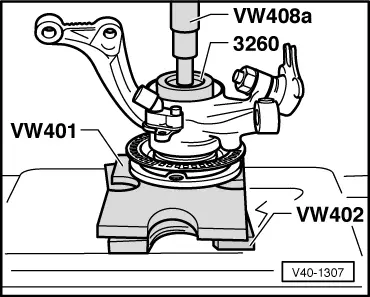

→ Fig.6 Pressing wheel bearing into wheel bearing housing

|

|

|

|

→ Fig.7 Pressing hub into wheel bearing |

|

|

|

→ Fig.8 Pressing track rod ball joint off steering arm

|