Polo Mk4

Note

Note

|

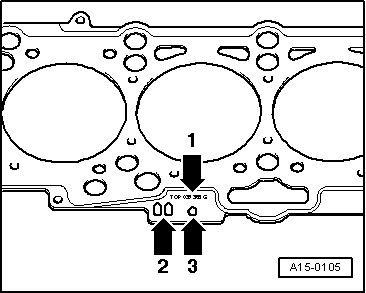

| 1 - | Head joint |

| q | Replace |

| q | Observe identification → Fig. |

| q | After replacing, completely renew cooling fluid |

| 2 - | 20 Nm |

| 3 - | Engine head |

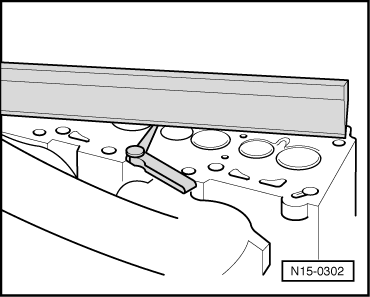

| q | Check bending → Fig. |

| q | Remove and install → Chapter. |

| q | After replacing, completely renew cooling fluid |

| 4 - | Suspension eyelet |

| 5 - | 8 Nm |

| q | For engine cover |

| 6 - | Head fastening screw |

| q | Replace |

| q | Observe installation and removal sequence → Chapter, remove and install head |

| 7 - | Oil deflector |

| 8 - | Head cover |

| q | With vulcanized seal |

| 9 - | Sealing ring |

| q | Replace when damaged |

| 10 - | Container cover |

| q | Replace joint if damaged |

| 11 - | Vent tube |

| 12 - | Braces |

| 13 - | Pressure regulating valve |

| q | For carter ventilation device |

| 14 - | Joint |

| q | Replace when damaged |

| 15 - | 10 Nm |

| 16 - | Injection tubes |

| q | Tighten screw at 25 Nm. |

| q | Remove with star wrench 3035 |

| q | Always remove complete tube set |

| q | Do not change bending |

| 17 - | Support |

| q | For engine cover |

| 18 - | 20 Nm |

| 19 - | Vacuum pump |

| q | For servo-brake |

| 20 - | 20 Nm |

| 21 - | Joint |

| q | Replace |

Note

Note

|

|