Polo Mk4

Note

Note

|

| 1 - | Upper cover from mechanical distribution |

| 2 - | Indented belt |

| q | Before removal, note down direction of rotation |

| q | Check wear |

| q | Do not fold |

| q | Remove and install, adjust → Chapter. |

| 3 - | 10 Nm |

| q | Replace |

| 4 - | 25 Nm |

| 5 - | 100 Nm |

| 6 - | Valve command shaft gear |

| 7 - | Cube |

| q | With rotation sensor. |

| q | To tighten and loosen, use the support -T10051- |

| q | To remove use pulling device -T10052- |

| q | Remove and install → Chapter, remove and install valve command shaft |

| 8 - | Rear cover from mechanical distribution |

| 9 - | Sealing scoop |

| q | Replace when damaged |

| 10 - | Sensor Hall -G40- |

| q | For the valve command shaft position |

| q | For removal take out sealing scoop → Item on the rear of mechanical distribution protector |

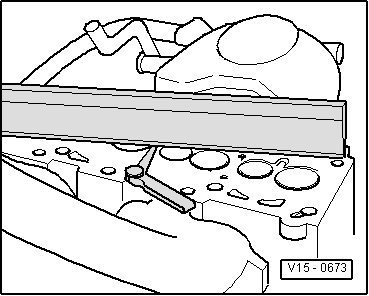

| 11 - | Head screw |

| q | Observe sequence when loosing and tightening → Chapter, Remove and install head |

| q | before assembly place washers on the head → Item, → Item |

| 12 - | Head cover |

| q | Before installation, carefully clean head sealing surface with a clean cloth |

| 13 - | Pressure regulator valve |

| q | For carter vent device |

| 14 - | To the turbo-compressor |

| 15 - | Container cover |

| q | Replace joint if damaged |

| 16 - | Sealing scoop |

| q | Replace when damaged |

| 17 - | 10 Nm |

| q | Observe tightening sequence → Chapter, Head cover - remove and install |

| 18 - | Head cover joint |

| q | Replace when damaged |

| q | Before placing seal transitions with “AMV 174 004 01” → Chapter, Head cover - remove and install |

| 19 - | 20 Nm |

| 20 - | Suspension eyelet |

| 21 - | Unit-pump-injector |

| q | Remove and install → Chapter. |

| 22 - | 10 Nm |

| 23 - | -Central connection |

| q | For unit - pump -injector |

| 24 - | From power brake |

| 25 - | Vacuum pump |

| q | To power brake |

| q | Check → Chapter. |

| q | Remove and install → Chapter. |

| 26 - | Supply hose |

| q | From fuel filter. → Chapter, → Item |

| q | White or with white marking |

| q | Ensure firm fixing |

| q | Ensure with spring clamps |

| 27 - | Return hose |

| q | To fuel filter → Chapter, → Item |

| q | Blue or blue marking, respectively |

| q | Ensure firm fixing |

| q | Ensure with spring clamps |

| 28 - | Joint |

| q | Replace |

| 29 - | Screw |

| 30 - | Head |

| q | Remove and install → Chapter. |

| q | After replacement, fully replace cooling fluid |

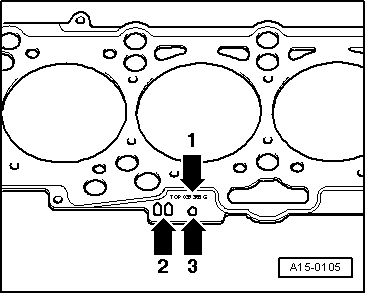

| 31 - | Head joint |

| q | Replace |

| q | Verify identification → Fig. |

| q | After replacing, fully replace cooling fluid |

| 32 - | Glower plug |

| q | 15 Nm |

| q | Check → Chapter. |

| 33 - | Tension pulley |

| 34 - | 20 Nm + 45 ° |

Note

Note

|

|