| t

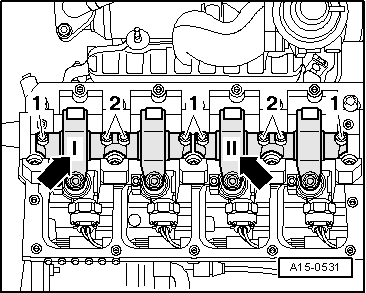

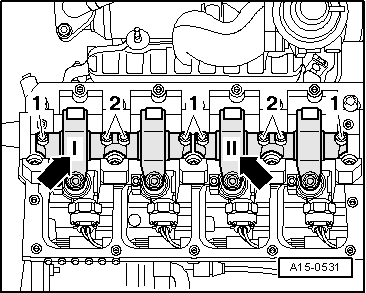

| During installation of valve command shaft, cylinder 1 cams must be turned upwards. |

| t

| Do not invert caps used (identify) |

| t

| When installing valve command shaft ensure cap lugs are duly placed on bearing caps and head. |

| t

| Before assembly, pay attention to bearing caps to ensure head screw washers are placed on head. |

| –

| Lubricate valve command shaft contact surfaces. |

| –

| Tighten bearings 2 and 4 caps alternately in a cross pattern with 8 Nm + 90 ° |

| –

| Install bearings 5, 1 and 3 caps and tighten with 8 Nm + 90 ° |

Note | t

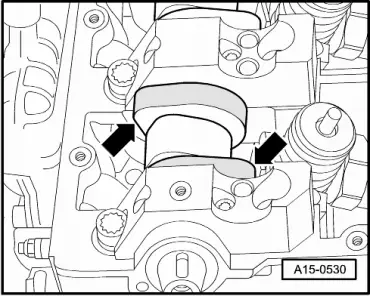

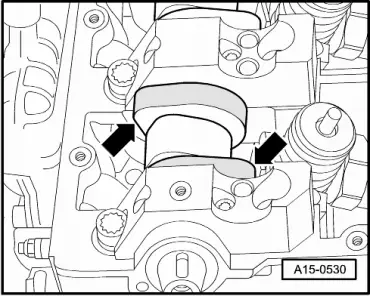

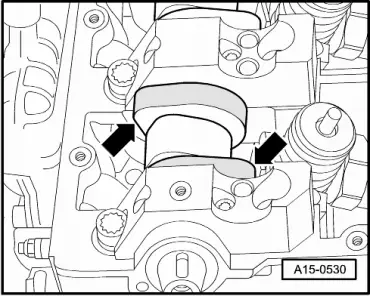

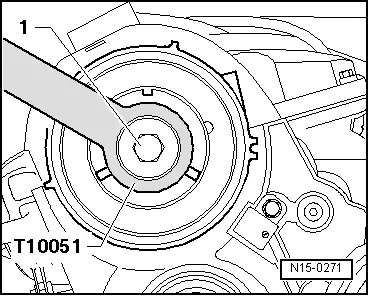

| Seal bearings 1 and 5 separation surfaces with AMV 174 004 01 → Fig., → Fig.. |

| t

| Bearing 5 cap must align with head external ridge, otherwise it may cause tandem pump to leak. |

| –

| Assemble sealing ring for valve command shaft → Chapter. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note