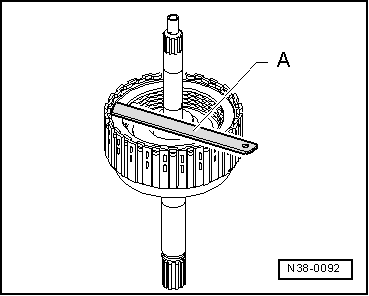

| Fig.4 - Check if the clutch works |

| –

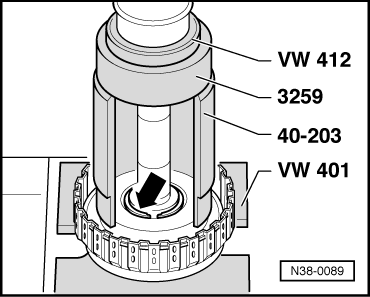

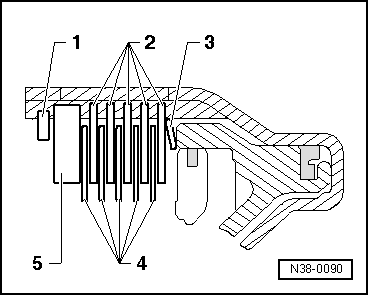

| Before assembling the plunger, apply ATF over the sealing lips and the retainers. |

| –

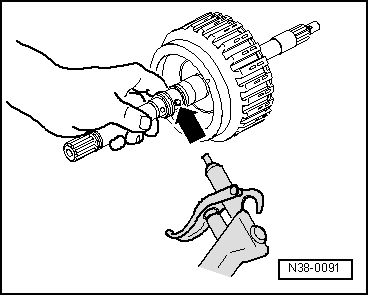

| Slightly turn the plunger when assembling it |

| –

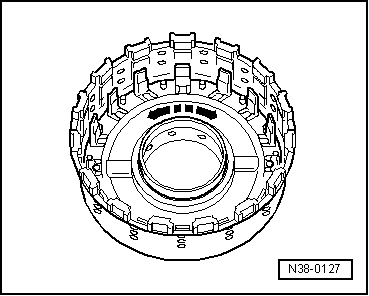

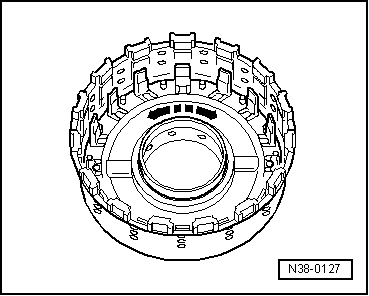

| Once the plunger is assembled in the clutches or the brakes, it must be able to be manually turned easily in both directions -arrows-. |

| –

| If not, the sealing lips or the retainers may not be completely inserted or are damaged. |

| –

| Disassemble the plunger if such abnormality occurs. |

| –

| Check if the sealing lips or the retainers are damaged and change them if necessary |

| –

| Assemble the plunger and review it again. |

|

|

|