| –

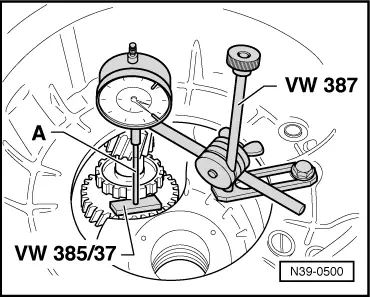

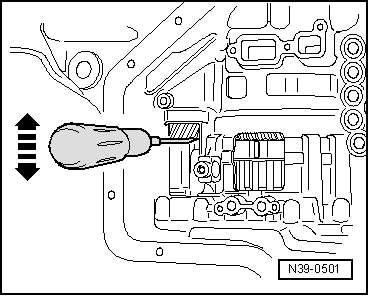

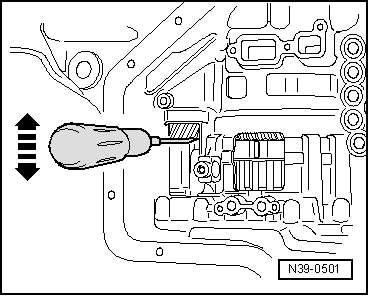

| Move the drive pinion shaft upward and downward with a screwdriver put in the driven pinion. |

| –

| Read the oscillation indicated in the gauge and write it (in the example: 1.02 mm). |

| Avoid turning the drive pinion shaft during the measurement, because the bearings would seat and the measurement result would be incorrect. |

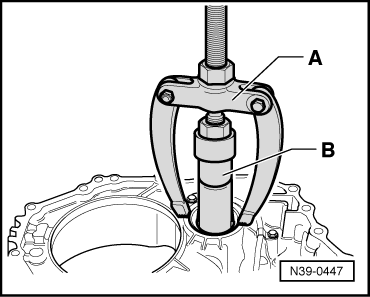

| Determination of the adjusting washer thickness |

| To reach the previous tension prescribed for this bearing, you must add a constant value pressure (0.18 mm) to the measurement value achieved. |

|

|

|