Polo Mk4

Note

Note

|

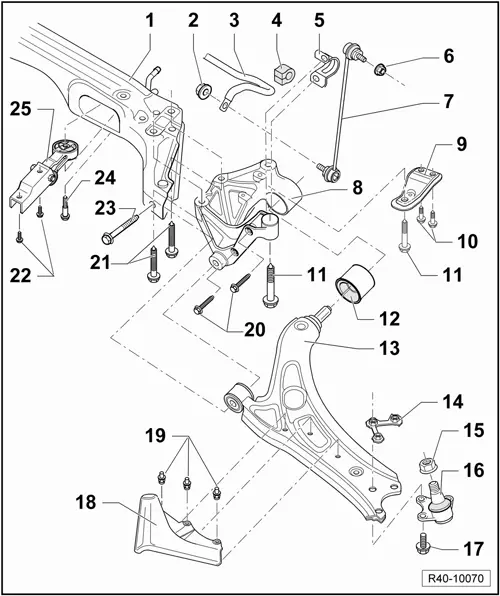

| 1 - | Auxiliary frame (sub-frame) |

| q | different versions |

| q | See: → Electronic Parts Catalogue„ETKA“ |

| q | Remove and install → Chapter |

| 2 - | Hexagonal nut |

| q | Self-locking |

| q | 40 Nm |

| q | Replace after each removal |

| 3 - | Anti-roll bar |

| The auxiliary frame (subframe) must be lower for the removal/installation of the anti-roll bar |

| q | Remove and install → Chapter |

| 4 - | Rubber support |

| q | Always replace both sides |

| q | See: → Electronic Parts Catalogue„ETKA“ |

| q | For its removal, loosen the fastening screws of the clamp with the rubber support |

| 5 - | Clamp |

| 6 - | Hexagonal nut |

| q | Self-locking |

| q | 40 Nm |

| q | Replace after each removal |

| 7 - | Coupling rod |

| q | Tighten the locknut upon aligning the vehicle |

| q | Only for vehicles with anti-roll bar |

| q | Between anti-roll bar and suspension column |

| 8 - | Console of the auxiliary frame (sub-frame) |

| q | Remove and install → Chapter |

| If the console thread is damaged, it can be repaired with a Heli-Coil thread insert |

| Repair the thread in the longitudinal member → Chapter |

| 9 - | Support |

| 10 - | Hex screws |

| q | 20 Nm + 90° |

| q | Replace after each removal |

| If the soldered nut thread is damaged, it can be repaired with a Heli-Coil thread insert |

| Repair the thread in the longitudinal member → Chapter |

| 11 - | Hexagonal head screw |

| q | 70 Nm + 90° |

| q | Replace after each removal |

| If the soldered nut thread is damaged, it can be repaired with a Heli-Coil thread insert |

| Repair the thread in the longitudinal member → Chapter |

| 12 - | Rubber support bearing for the console |

| q | different versions |

| q | See: → Electronic Parts Catalogue„ETKA“ |

| q | Remove and install → Chapter |

| 13 - | Wishbone (transversal) |

| q | Remove and install → Chapter |

| 14 - | Plate with nuts |

| 15 - | Hexagonal nut |

| q | Self-locking |

| q | 20 Nm + 90° |

| q | Replace after each removal |

| 16 - | Swivel guide |

| q | Check → Chapter |

| q | Remove and install → Chapter |

| q | Installation position → Chapter |

| 17 - | Hexagonal head screw |

| q | 20 Nm + 90° |

| q | Replace after each removal |

| 18 - | Air deflector plate |

| q | Only on vehicles with 13 chassis |

| 19 - | Spreader rivet |

| q | Only on vehicles with 13 chassis |

| 20 - | Hex screws |

| q | 20 Nm + 90° |

| q | Replace after each removal |

| 21 - | Hexagonal head screw |

| q | 50 Nm + 90° |

| q | Replace after each removal |

| follow the sequence for installing and tightening the screws: |

| t | First, tighten the hexagonal screw -position 23-, but do not tighten it definitely |

| t | Next, tighten the hexagonal screw -position 21-, but do not tighten it definitely |

| t | Finally, tighten the hexagonal screws alternately. |

| 22 - | Hexagonal head screw |

| q | 30 Nm + 90° |

| q | Replace after each removal |

| 23 - | Hexagonal head screw |

| q | 70 Nm + 90° |

| q | Replace after each removal |

| follow the sequence for installing and tightening the screws: |

| t | First, tighten the hexagonal screw -position 23-, but do not tighten it definitely |

| t | Next, tighten the hexagonal screw -position 21-, but do not tighten it definitely |

| t | Finally, tighten the hexagonal screws alternately. |

| 24 - | Hexagonal head screw |

| q | 40 Nm + 90° |

| q | Replace after each removal |

| 25 - | Pendular support |

WARNING

WARNING