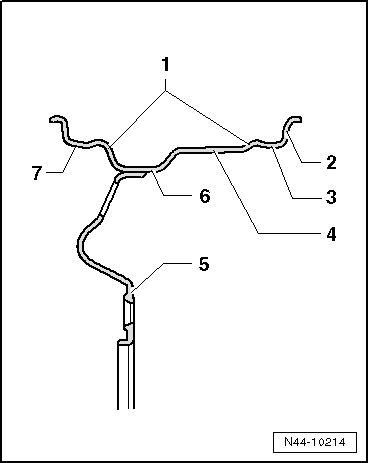

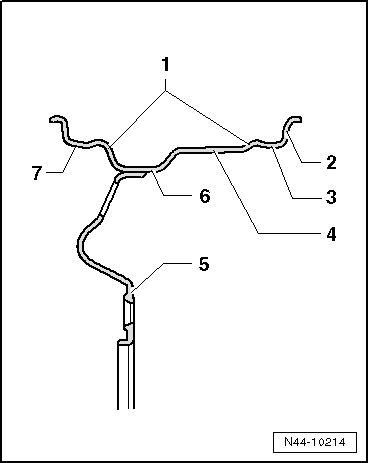

| The updated radial tyre for passenger vehicles are exclusively

assembled in safety wheels. These wheels have an elevation around

the shoulders -1-. |

| 1 - | protrusion (double protrusion H 2) |

| 3 - | inner shoulder of the wheel (for example, inclined shoulder) |

| 5 - | central disc of the wheel |

| 7 - | outer shoulder of the wheel (for example, inclined shoulder) |

| The protrusion avoids the compression of the tyre by wheel

shoulder if the vehicle is driven with insufficient inflation pressure. |

| When inflating the tyre, it may happen that the tyre bead

does not slide completely over the wheel's protrusion. |

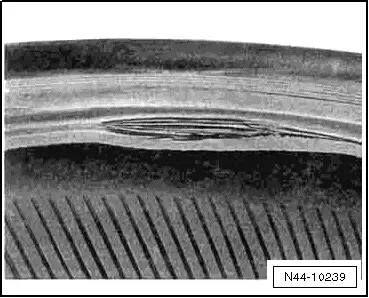

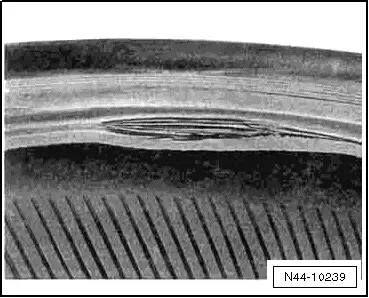

| In this case, there is the danger of bead core dilatation,

due to excessive inflation pressure, when the corresponding steel

wires break totally or partially. The slots in the tyre bead core

are not detectable from the outer portion. |

WARNING | t

| The tyres with damaged bead core do not have a good seating

on the wheel. These tyres represent a danger for the safety! |

| t

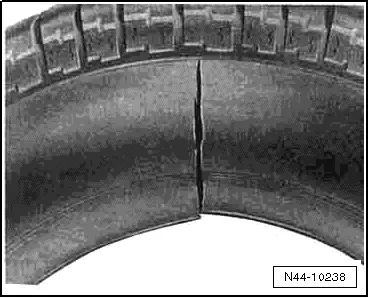

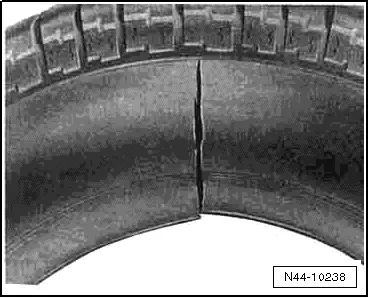

| Moreover, there is the danger of a bead core partially damaged

breaking completely, while the vehicle is being driven, and the tyre

may suddenly open. If the bead core breaks while the tyre is being

inflated, the case will also be destroyed. |

|

|

|

|

Note

Note

Note

Note