| t

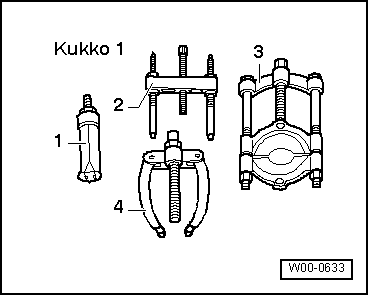

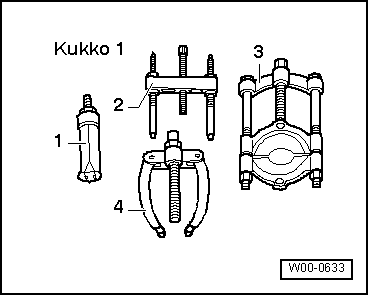

| -1-Internal puller -Kukko 21/6- |

| t

| -4-Counter support -Kukko 22/2- |

| It is necessary to readjust the output shaft when the following components are renewed: |

| l

| Sealing surfaces of clutch and gearbox housings must be free of sealant. |

| –

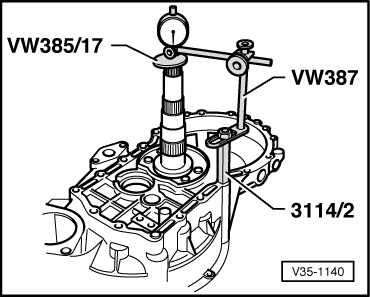

| Press outer ring of small tapered roller bearing to stop with 0.65 mm shim into clutch housing → Fig.. |

| –

| Insert output shaft and tighten nuts for bearing support to 25 Nm, then turn 90° further. |

| –

| Turn output shaft 20 to 30 times in one direction. |

Note | t

| The shaft must be turned in one direction so that the rollers of the tapered roller bearing settle in one direction. |

| t

| It is necessary to turn the shaft 20 to 30 times to achieve this. |

| t

| Otherwise the resulting reading will be incorrect. |

|

|

|

Note

Note