Polo Mk5

| Repairing gearbox housing and clutch housing |

| Special tools and workshop equipment required |

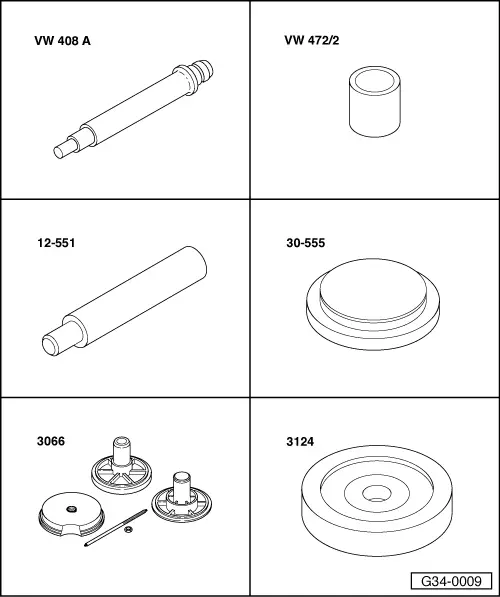

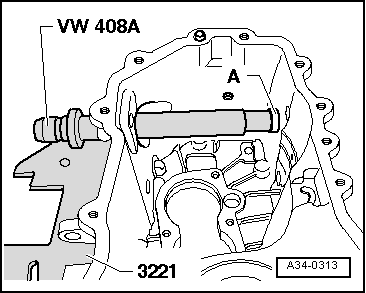

| t | Press tool -VW 408 A- |

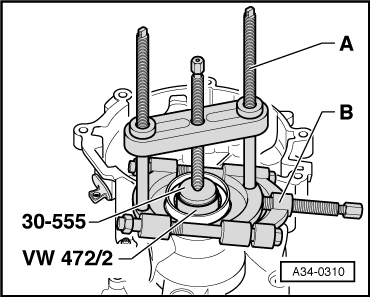

| t | Spacer sleeve -VW 472/2- |

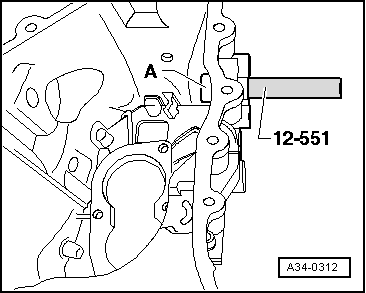

| t | Centring mandrel -12-551- |

| t | Thrust piece -30-555- |

| t | Spindle from assembly tool -3066- |

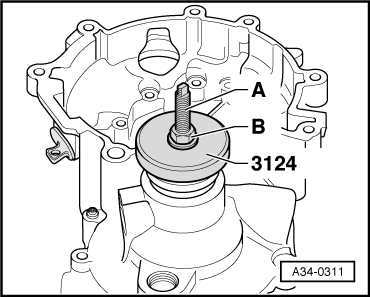

| t | Thrust piece -3124- |

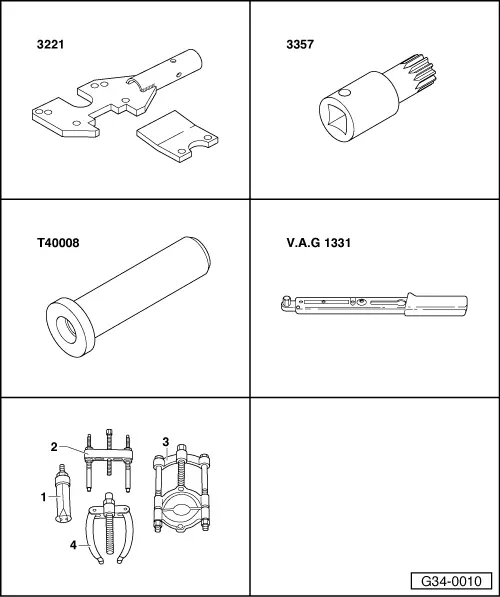

| t | Gearbox support -3221- (modifying → Chapter) |

| t | Multi-point bit -3357- |

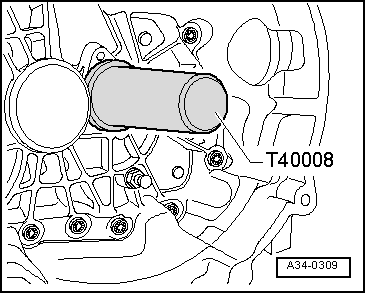

| t | Thrust piece -T40008- |

| t | Torque wrench -V.A.G 1331- |

| t | -2-Puller -Kukko 18/1- |

| t | -3-Splitter -Kukko 17/1- |

| 1 - | Clutch housing |

| q | Made of either aluminium or magnesium. |

| q | Allocation → Electronic parts catalogue (ETKA) |

| q | If renewed, adjust differential → Chapter |

| 2 - | Input shaft seal |

| q | Lever out with a screwdriver |

| q | Driving in → Fig. |

| 3 - | Ball stud |

| q | Removing and installing → Item |

| 4 - | Oil seal for right flange shaft |

| q | Renewing with gearbox installed → Chapter |

| 5 - | Sleeve |

| q | For oil seal. |

| q | Pulling out → Fig. |

| q | Pulling in → Fig. |

| 6 - | Oil filler plug, torque setting → Fig. |

| 7 - | O-ring |

| q | Always renew |

| q | as of 11.02 discontinued in conjunction with ABS |

| 8 - | Speedometer sender -G22- |

| q | From 11.02 in conjunction with ABS replaced by a plug |

| 9 - | Bolt, 5 Nm + turn 90° further |

| q | Always renew |

| 10 - | Shim S2 |

| q | For differential |

| q | Determining thickness → Chapter |

| 11 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pulling out and pressing in → Chapter |

| q | If renewed, adjust differential → Chapter |

| 12 - | Bolt, 5 Nm + turn 90° further |

| q | Always renew |

| 13 - | Tapered roller bearing outer race |

| q | For differential |

| q | Pulling out and pressing in → Chapter |

| q | If renewed, adjust differential → Chapter |

| 14 - | Shim S1 |

| q | For differential |

| q | Always 1 mm thick |

| q | For aluminium gearbox housings only: shim S1 discontinued from gearbox date 04 12 6 → Fig. |

| q | Bearing seat for tapered roller bearing outer race adapted in gearbox housing |

| 15 - | Dowel sleeve |

| q | Qty. 2 |

| 16 - | Gearbox housing |

| q | Made of either aluminium or magnesium. |

| q | For aluminium gearbox housings only: shim S1 discontinued from gearbox date 04 12 6 → Fig. |

| q | Bearing seat for tapered roller bearing outer race adapted in gearbox housing |

| q | If renewed, adjust differential → Chapter |

| q | Allocation → Electronic parts catalogue (ETKA) |

| 17 - | Oil drain plug, torque setting → Fig. |

| 18 - | Oil seal for left flange shaft |

| q | Renewing with gearbox installed → Chapter |

| 19 - | Sleeve |

| q | For selector shaft |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 20 - | Magnet |

| q | Held in place by housing joint surface |

| 21 - | Cover plate |

| q | Apply sealant -AMV 188 200 03- before bolting on. |

| 22 - | Retaining ring |

| q | Insert in groove of cylindrical roller bearing → Item. |

| 23 - | Retaining ring |

| q | Insert in groove of cylindrical roller bearing → Item. |

| 24 - | Cylindrical roller bearing |

| q | For input shaft |

| q | Removing and installing → Chapter |

| 25 - | Cylindrical roller bearing |

| q | For output shaft |

| q | Removing and installing → Chapter |

| 26 - | Plug |

| q | Insert into hole in clutch housing. |

| q | Not fitted in all gearboxes |

|

|

|

|

|

|

|

|

Note

Note