Polo Mk5

| Adjusting differential |

| Special tools and workshop equipment required |

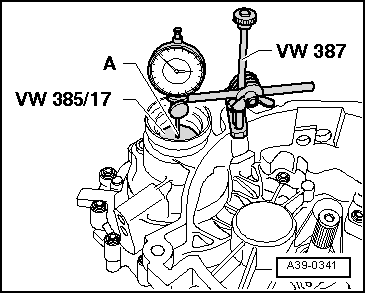

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

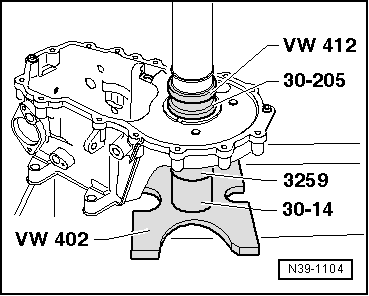

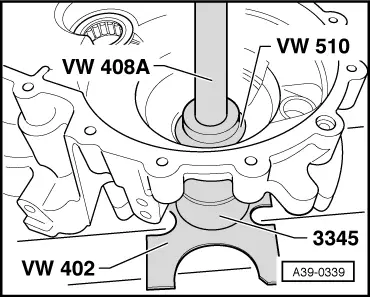

| t | Pressure plate -VW 402- |

| t | Pressure plate -VW 401- |

| t | Press tool -VW 408- |

| t | Press tool -VW 412- |

| t | Thrust pad -VW 510- |

| t | Tube -30 - 14- |

| t | Tube -2040- |

| t | Tube -3259- |

| t | Wheel bearing tube -3345- |

| t | Torque wrench -V.A.G 1331- |

| t | Dial gauge |

|

|

|

|

Note

Note

|

|

|

|

|

|