Polo Mk5

| Dismantling and assembling selector forks |

| Special tools and workshop equipment required |

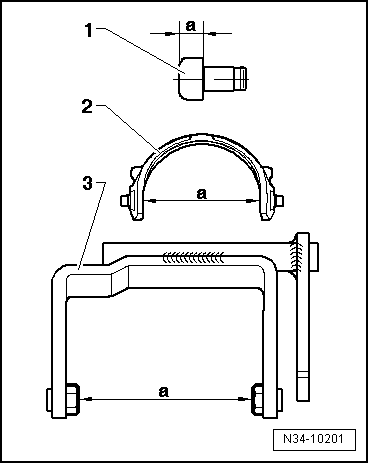

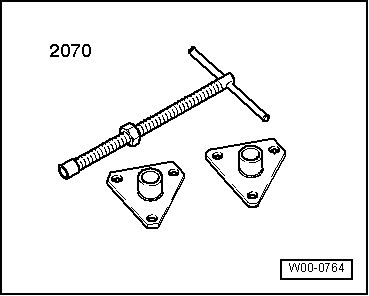

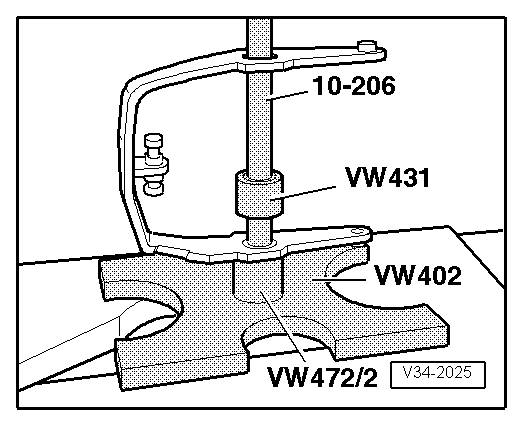

| t | Pressure plate -VW 402- |

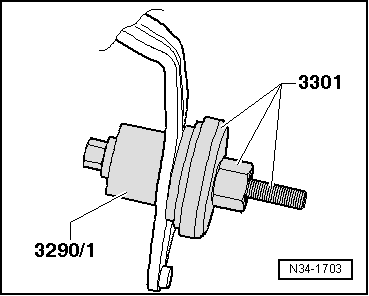

| t | Thrust piece -3290/1- |

| t | Assembly tool -3301- |

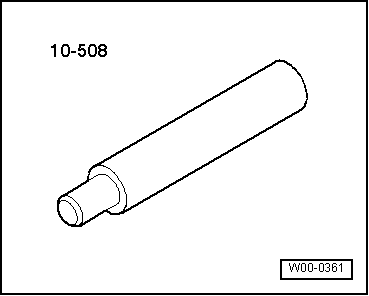

| t | Thrust piece -VW 431- |

| t | Spacer sleeve -VW 472/2- |

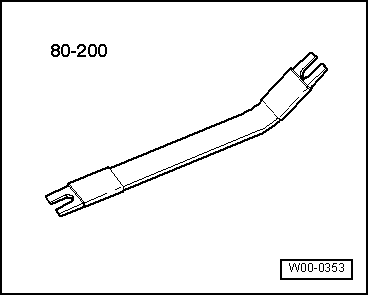

| t | Drift -10 - 206- |

|

|

|

|

|

|

|

|

Note

Note| It is not necessary to dismantle the selector fork group → Item in order to dismantle and assemble selector segments, lock washers and angular contact ball bearings. |

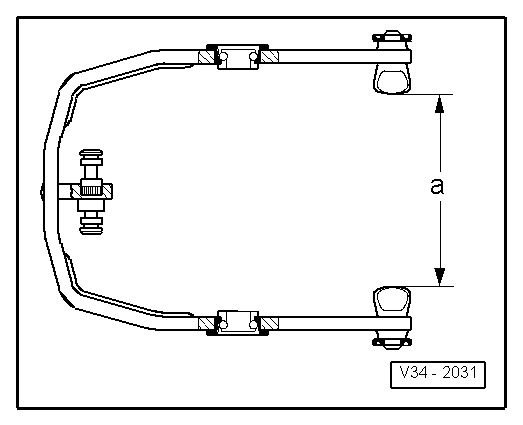

| 1 - | Selector fork group with selector plate |

| 2 - | Selector segment for 3rd and 4th gear |

| q | After installation, selector segment must still rotate freely |

| q | Identification → Fig. |

| 3 - | Angular contact ball bearing |

| q | Qty. 4 |

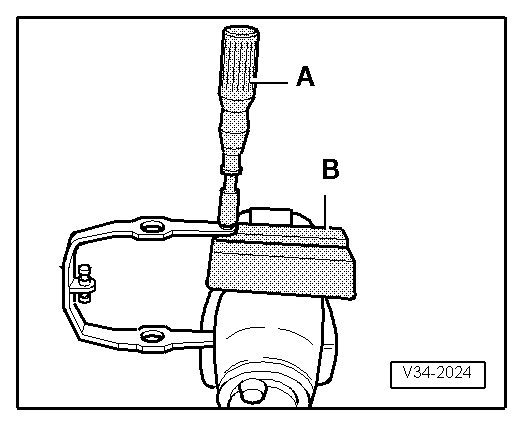

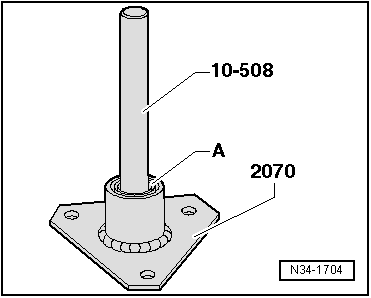

| q | Removing → Fig. |

| q | Press inner race into outer race → Fig. |

| q | Installing → Fig. |

| 4 - | Lock washer |

| q | Always renew |

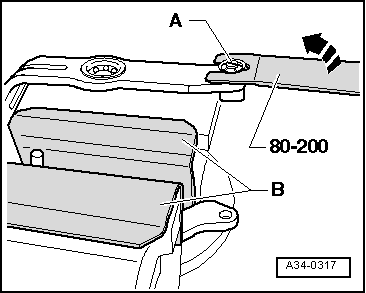

| q | Removing → Fig. |

| q | Installing → Fig. |

| 5 - | 1st/2nd gear selector segment |

| q | Identification → Fig. |

| q | After lock washer is installed, segment must still rotate freely |

| q | Selector fork with selector segment → Fig. |

| 6 - | Selector fork for 5th and 6th gears with selector segments |

| q | Selector segment is permanently connected to selector fork. |

| q | Identification → Fig. |

| 7 - | Pivot pin |

| q | For selector fork for 5th and 6th gears |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|