Polo Mk5

| Dismantling and assembling output shaft |

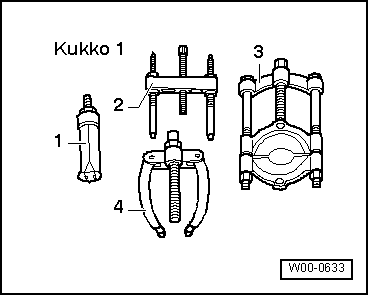

| Special tools and workshop equipment required |

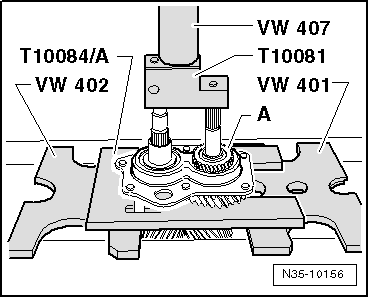

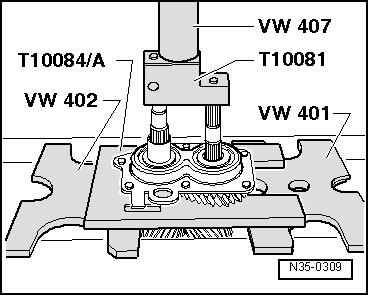

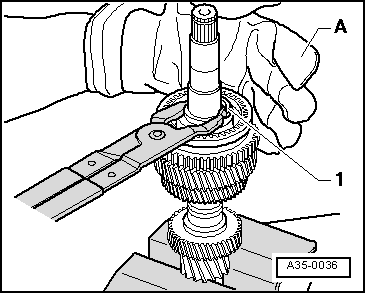

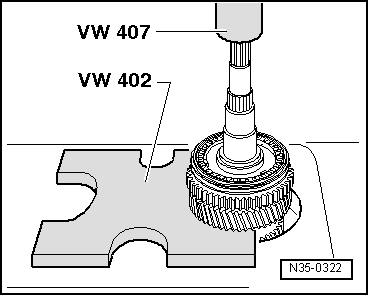

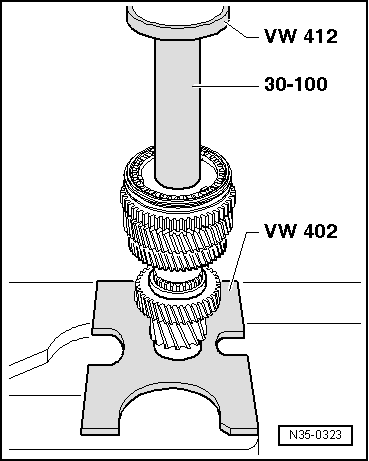

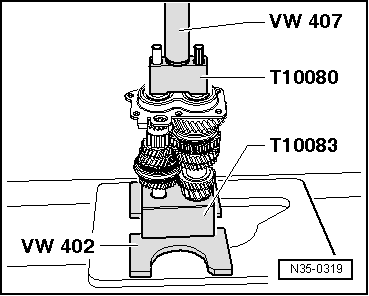

| t | Pressure plate -VW 402- |

| t | Press tool -VW 407- |

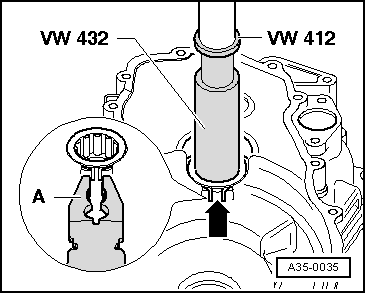

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Thrust piece -VW 432- |

| t | Drift sleeve -30 - 100- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

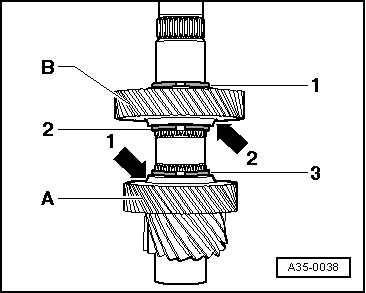

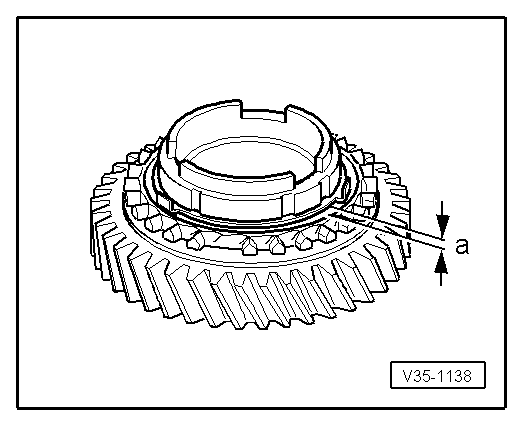

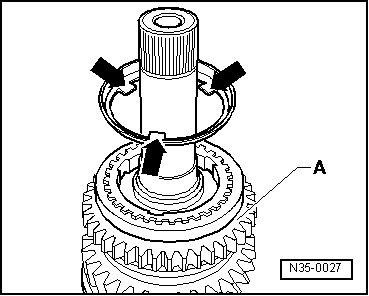

| Gap „a“ | Installation dimension | Wear limit |

| 1st and 2nd gears | 0.75 … 1.25 mm | 0.3 mm |

|

|

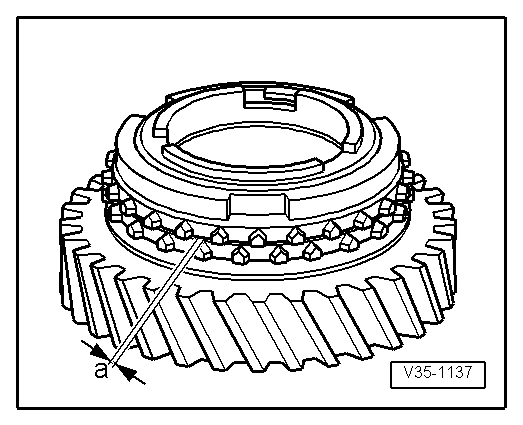

| Gap „a“ | Installation dimension | Wear limit |

| 1st and 2nd gears | 1.2 … 1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING