Polo Mk5

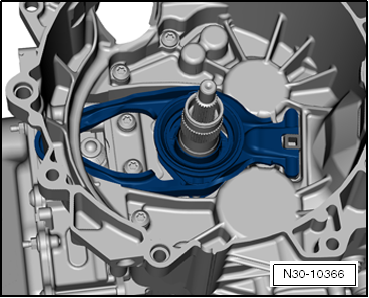

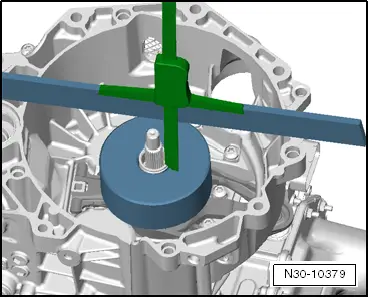

| Overview of clutch actuation: |

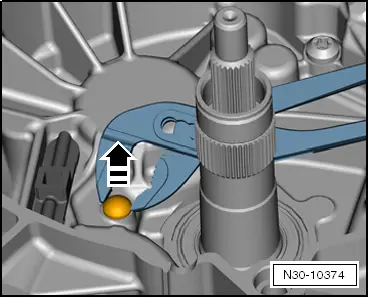

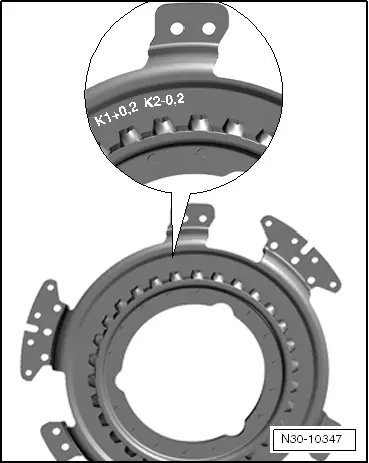

| 1 - | Shim for „K 1“ |

| q | → Chapter „Adjusting position of clutch engagement bearings K 1 and K 2“ |

| 2 - | Large engaging lever for „K 1“ |

| q | With engagement bearing |

| 3 - | Hinge mounting |

| q | For large engaging lever „K 1“ |

| q | Is not renewed |

| 4 - | Small engagement bearings for „K 2“ |

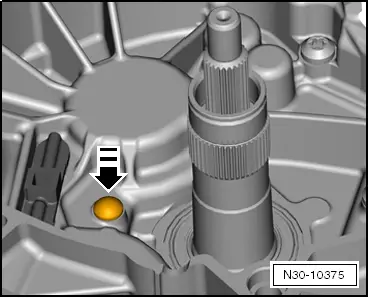

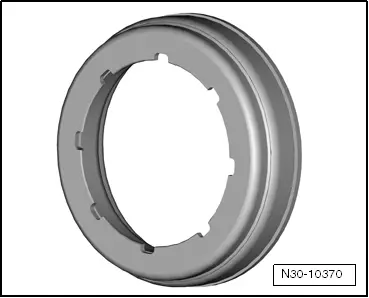

| 5 - | Shim for „K 2“ |

| q | → Chapter „Adjusting position of clutch engagement bearings K 1 and K 2“ |

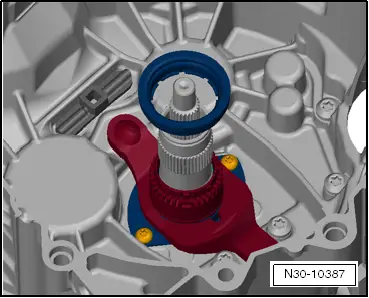

| 6 - | Upper part of guide sleeve |

| q | Small small engaging lever „K 2“ |

| q | is removed and installed together with lower part of guide sleeve |

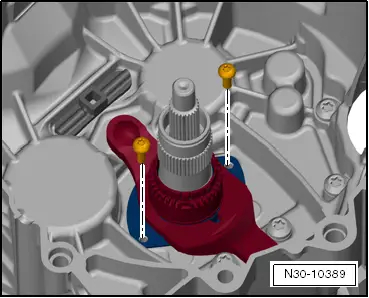

| 7 - | Small engaging lever for „K 2“ |

| q | is removed and installed together with upper and lower part of guide sleeve |

| 8 - | Ball stud |

| q | Small small engaging lever „K 2“ |

| q | → Chapter „Adjusting position of clutch engagement bearings K 1 and K 2“ |

| 9 - | Bolts |

| q | 8Nm + 90° |

| q | Always renew |

| 10 - | Lower part of guide sleeve |

| q | Small small engaging lever „K 2“ |

| q | is removed and installed together with upper part of guide sleeve |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

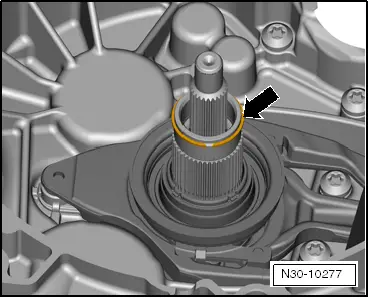

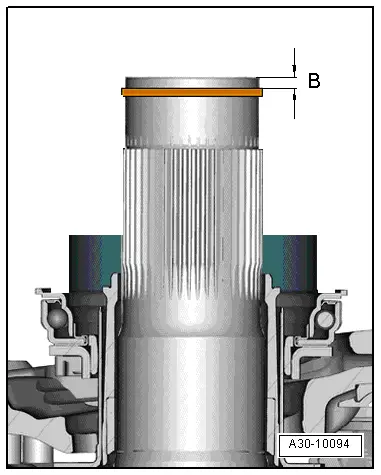

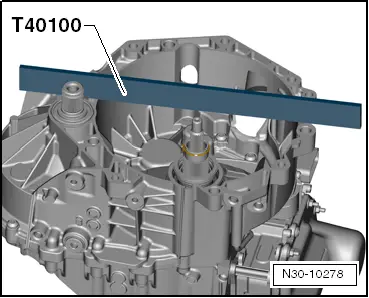

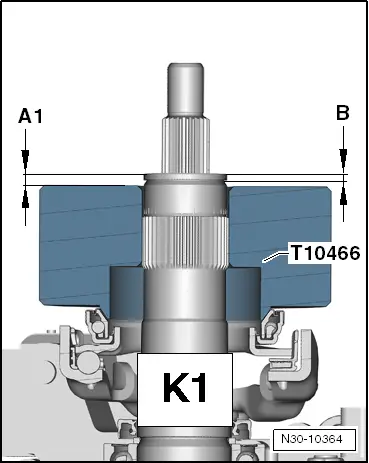

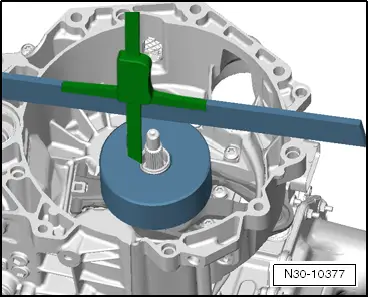

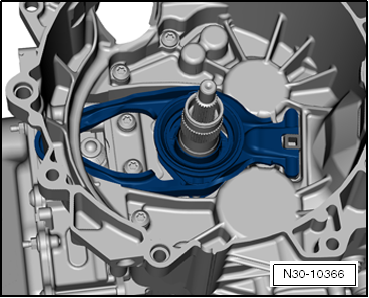

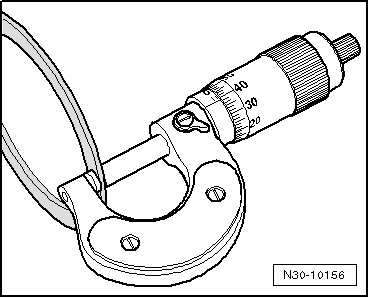

| Dimension „A 1“ | |

| – | Dimension „B“ |

| = | Actual height tolerance of clutch engagement bearing „K 1“ |

|

Note

Note

|

|

| Height tolerance of engagement bearing „K 1“ | |

| –/+ | Clutch tolerance of clutch „K 1“ |

| = | Calculated thickness of shim „SK 1“ |

|

|

|

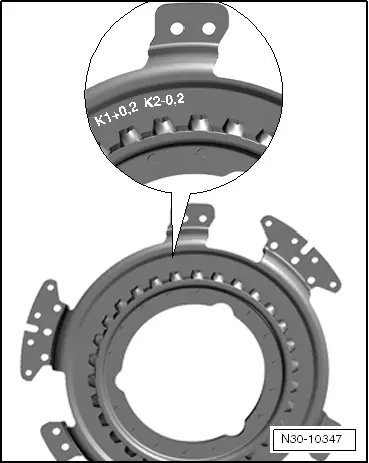

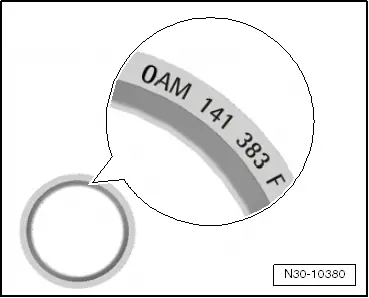

| Calculated thickness of shim mm | Available shims Thickness in mm | Part number of shim |

| 1.21 … 1.60 | 1.50 | 0AM 141 383 |

| 1.61 … 1.80 | 1.70 | 0AM 141 383 A |

| 1.81 … 2.00 | 1.00 | 0AM 141 383 B |

| 2.01 … 2.20 | 2.10 | 0AM 141 383 C |

| 2.21 … 2.40 | 2.30 | 0AM 141 383 D |

| 2.41 … 2.60 | 2.50 | 0AM 141 383 E |

| 2.61 … 2.80 | 2.70 | 0AM 141 383 F |

| 2.81 … 3.00 | 2.00 | 0AM 141 383 G |

| 3.01 … 3.20 | 3.10 | 0AM 141 383 H |

| 3.21 … 3.40 | 3.30 | 0AM 141 383 J |

| 3.41 … 3.80 | 3.50 | 0AM 141 383 K |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

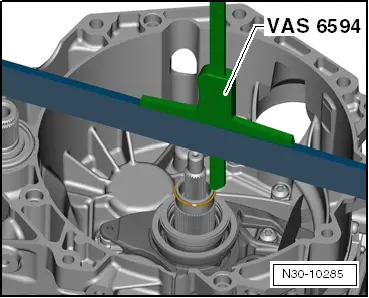

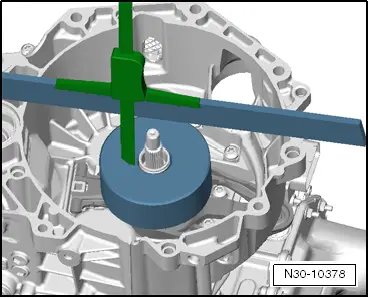

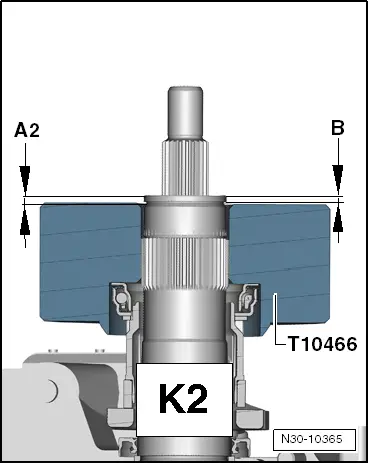

| Dimension „A 2“ | |

| – | Dimension „B“ |

| = | Actual height tolerance of clutch engagement bearing „K 2“ |

|

Note

Note

|

|

| Height tolerance of engagement bearing „K 2“ | |

| –/+ | Clutch tolerance of clutch „K 2“ |

| = | Calculated thickness of shim „SK 2“ |

|

|

|

| Calculated thickness of shim mm | Available shims Thickness in mm |

| 0.31 … 0.00 | 0.80 |

| 0.01 … 1.10 | 1.00 |

| 1.11 … 1.30 | 1.20 |

| 1.31 … 1.50 | 1.40 |

| 1.51 … 1.70 | 1.60 |

| 1.71 … 1.00 | 1.80 |

| 1.01 … 2.10 | 2.00 |

| 2.11 … 2.30 | 2.20 |

| 2.31 … 2.50 | 2.40 |

| 2.51 … 2.70 | 2.60 |

| 2.71 … 3.30 | 2.80 |

|

Caution

Caution WARNING

WARNING