Polo Mk5

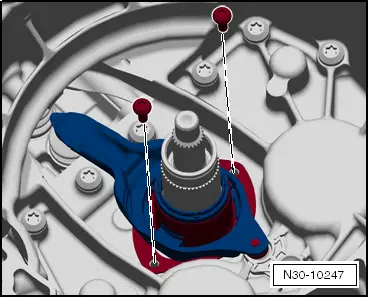

| Overview of clutch actuation |

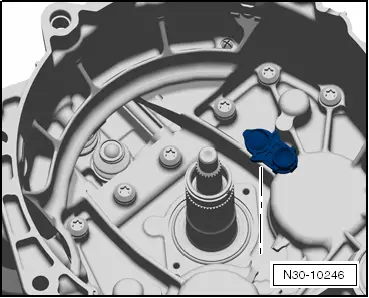

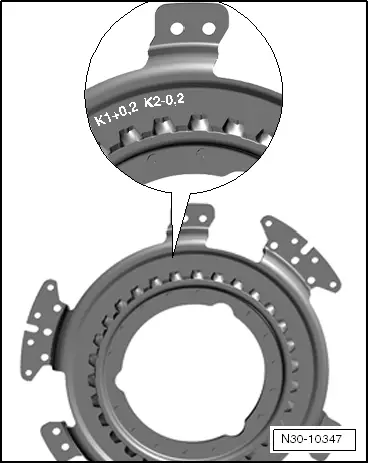

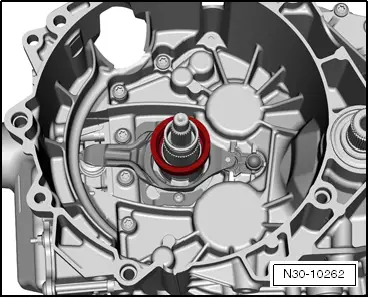

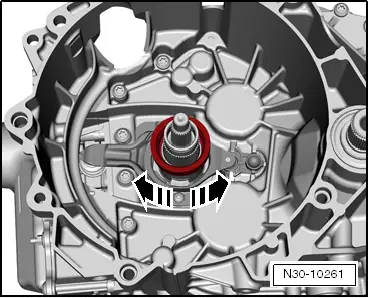

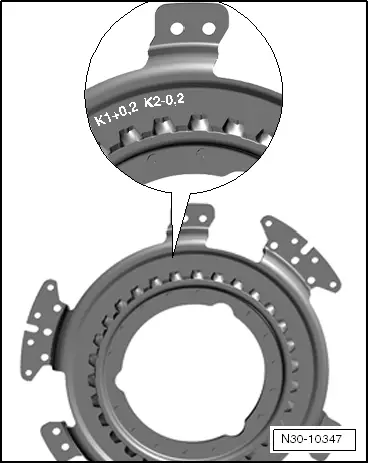

| 1 - | Small engaging lever for »K 2« |

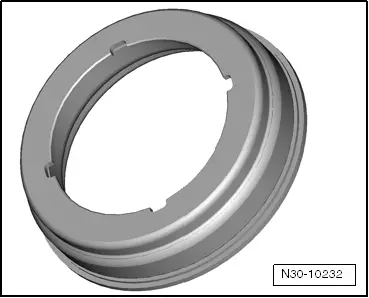

| 2 - | Shim for »K 2« |

| 3 - | Engagement bearings for »K 2« |

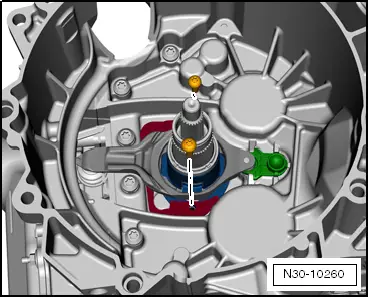

| 4 - | Large engaging lever for „K 1“ |

| q | With large engagement bearing |

| 5 - | Shim for „K 1“ |

| 6 - | Bolts |

| q | 8Nm + 90° |

| q | Always renew |

| 7 - | Clip |

| q | No present in some older gearboxes |

| 8 - | Support |

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

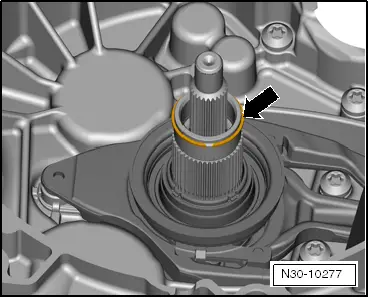

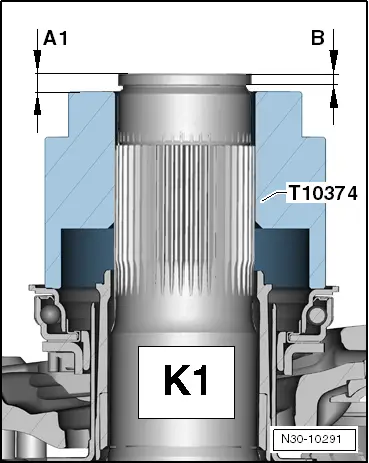

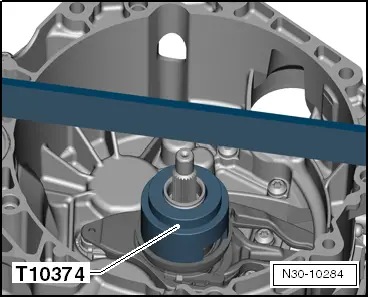

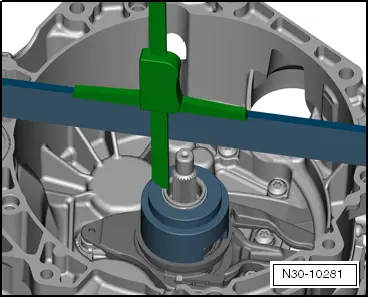

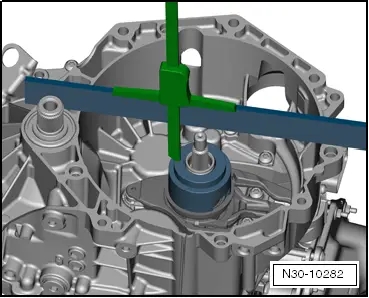

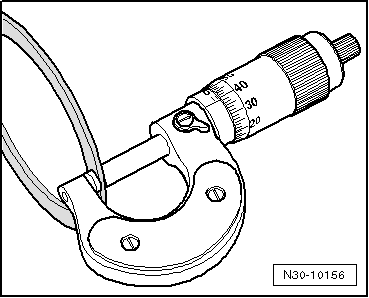

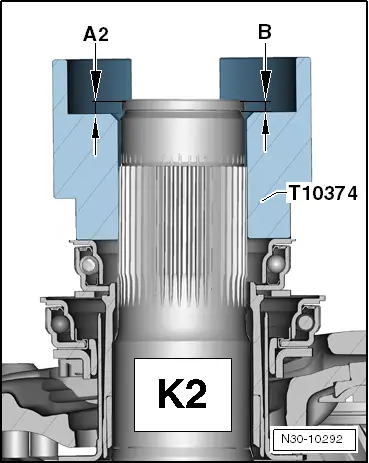

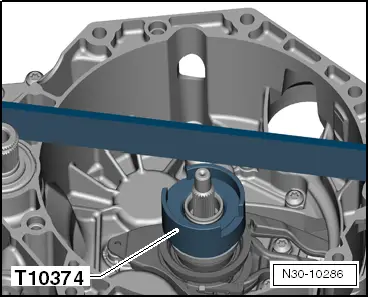

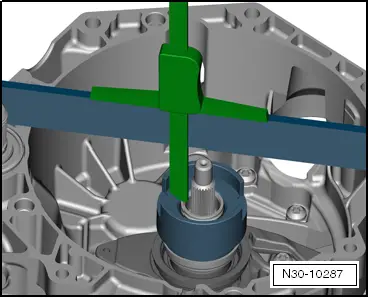

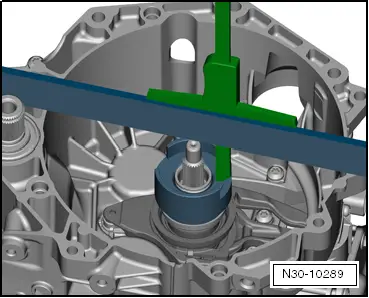

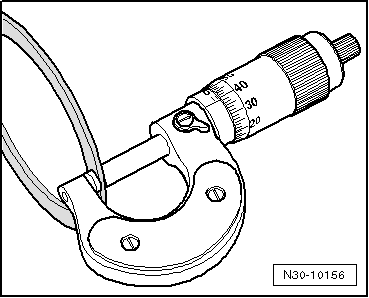

| Dimension „A 1“ | |

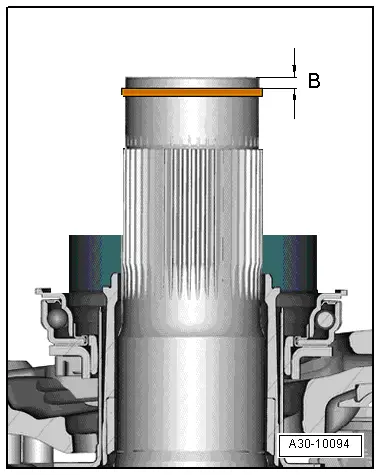

| – | Dimension „B“ |

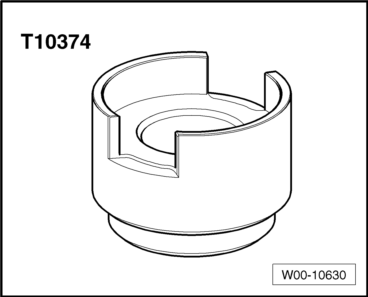

| + | Exterior height end gauge -T10374- (51.81 mm; fixed value) |

| = | Actual installation depth of clutch engagement bearing „K 1“ |

Note

Note

|

| Actual value of engagement bearing installation depth | |

| – | Specification of engagement bearing installation depth (50.08 mm; fixed value) |

| = | Clearance of clutch „K 1“ |

|

Note

Note

|

|

| Clearance of clutch „K 1“ | |

| –/+ | Clutch tolerance of clutch „K 1“ |

| = | Calculated thickness of shim „SK 1“ |

|

|

|

| Calculated thickness of shim mm | Available shims Thickness in mm |

| 0.31 … 0.00 | 0.80 |

| 0.01 … 1.10 | 1.00 |

| 1.11 … 1.30 | 1.20 |

| 1.31 … 1.50 | 1.40 |

| 1.51 … 1.70 | 1.60 |

| 1.71 … 1.00 | 1.80 |

| 1.01 … 2.10 | 2.00 |

| 2.11 … 2.30 | 2.20 |

| 2.31 … 2.50 | 2.40 |

| 2.51 … 2.70 | 2.60 |

| 2.71 … 3.30 | 2.80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

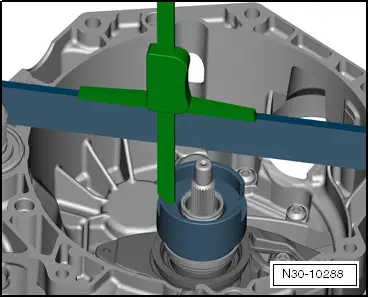

| Dimension „A 2“ | |

| – | Dimension „B“ |

| + | Interior height end gauge -T10374- (36.20 mm; fixed value) |

| = | Actual installation depth of clutch engagement bearing „K 2“ |

Note

Note

|

| Actual value of engagement bearing installation depth | |

| – | Specification of engagement bearing installation depth (34.35 mm; fixed value) |

| = | Clearance of clutch „K 2“ |

|

Note

Note

|

|

| Clearance of clutch „K 2“ | |

| –/+ | Clutch tolerance of clutch „K 2“ |

| = | Calculated thickness of shim „SK 2“ |

|

|

|

| Calculated thickness of shim mm | Available shims Thickness in mm |

| 0.31 … 0.00 | 0.80 |

| 0.01 … 1.10 | 1.00 |

| 1.11 … 1.30 | 1.20 |

| 1.31 … 1.50 | 1.40 |

| 1.51 … 1.70 | 1.60 |

| 1.71 … 1.00 | 1.80 |

| 1.01 … 2.10 | 2.00 |

| 2.11 … 2.30 | 2.20 |

| 2.31 … 2.50 | 2.40 |

| 2.51 … 2.70 | 2.60 |

| 2.71 … 3.30 | 2.80 |

|

Caution

Caution