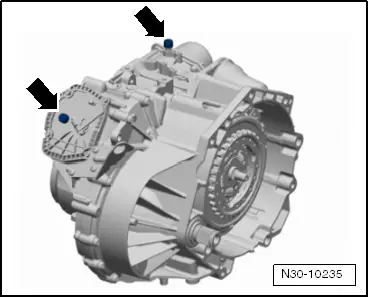

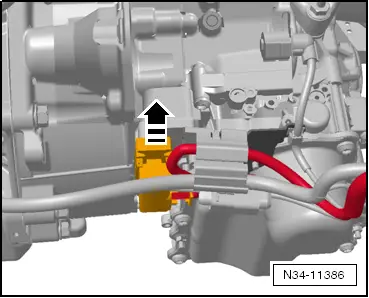

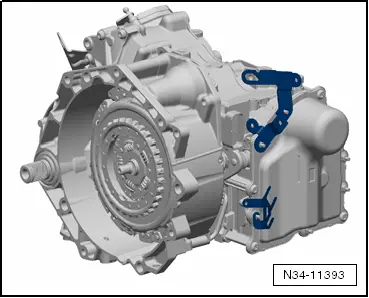

| The gearbox is removed downwards separately, without engine. »From above« |

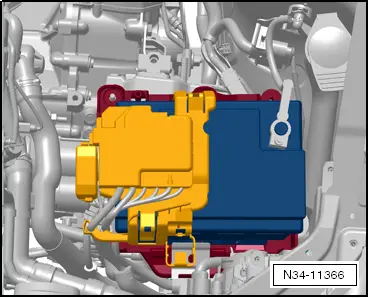

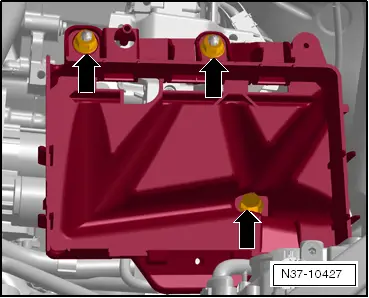

| Remove battery, air filter and starter. |

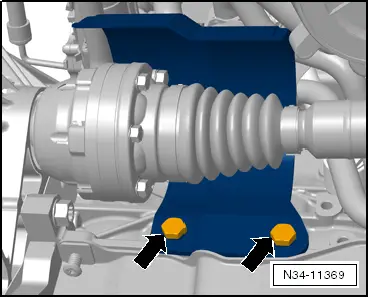

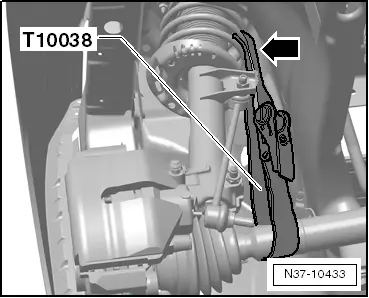

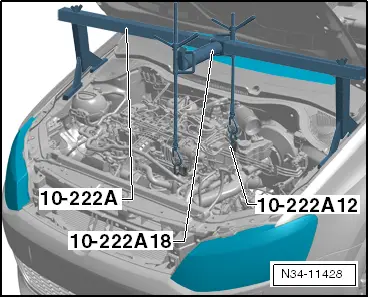

| Remove noise insulation beneath engine, front left wheel housing liner and subframe with pendulum support. Secure drive shafts so that they do not disrupt removal. However, leave them on the suspension struts. The gearbox is removed downwards separately, without engine. |

| Subframe must be secured. |

| –

| Raise vehicle. All 4 supports of lifting platform must be at same height. |

| –

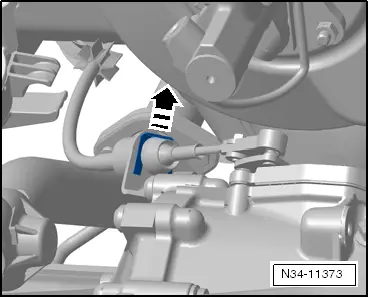

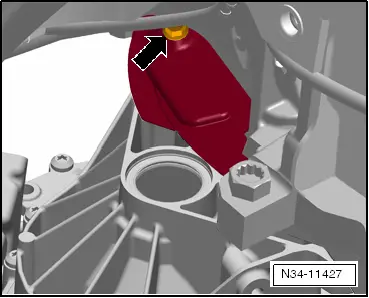

| Move selector lever to position »P« position. |

| –

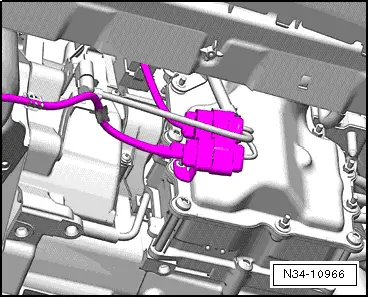

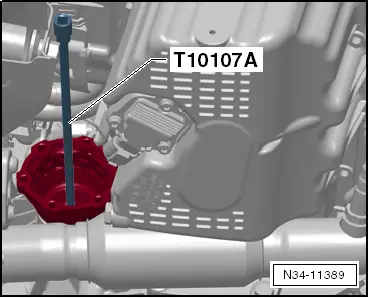

| Remove engine cover from cylinder head. |

|

|

|