| –

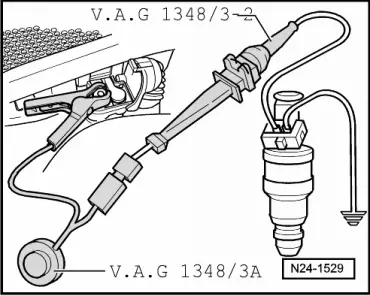

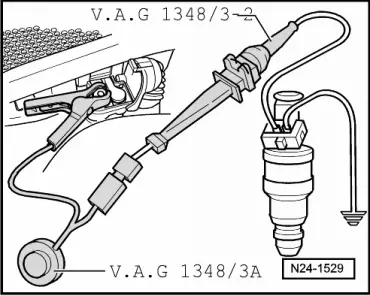

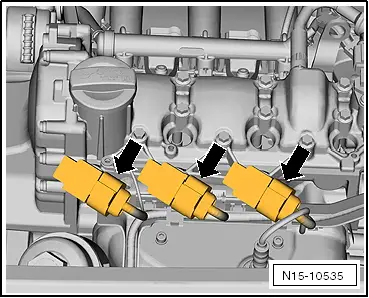

| Connect a contact of injector to be tested to engine earth using auxiliary cables from auxiliary measuring set -V.A.G 1594C-. |

| –

| Connect second injector contact with auxiliary cable to remote control for V.A.G 1348 -V.A.G 1348/3A- using adapter cable -V.A.G 1348/3-2-. |

| –

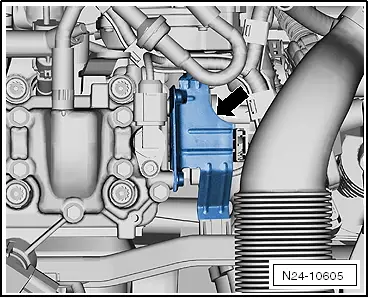

| Connect crocodile clip to positive battery pole in engine compartment. |

| –

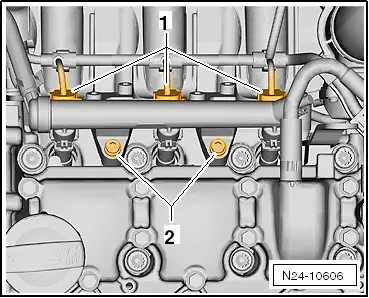

| Remove three measuring containers from injection rate tester -V.A.G 1602-. |

| –

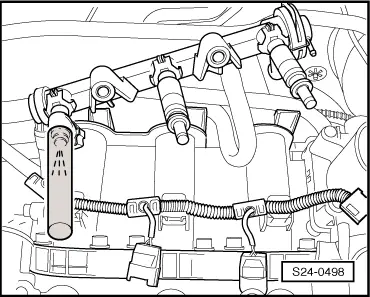

| Pull fuel rail out of intake manifold. |

| –

| Position measuring glass under injector to be tested. |

| –

| Operate remote control for V.A.G 1348 -V.A.G 1348/3A- for 30 seconds. |

| –

| Repeat check on other injectors. |

Note | Use one measuring glass per injector. |

| –

| After all injectors have been activated, place measuring beakers on a level surface and compare the quantity injected. |

| Specification: 85…91 ml per injector. |

| If the measured values of one or more injectors are above or below the prescribed specifications: |

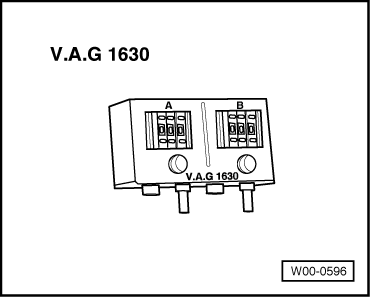

| Special tools and workshop equipment required |

|

|

|

Note

Note