| –

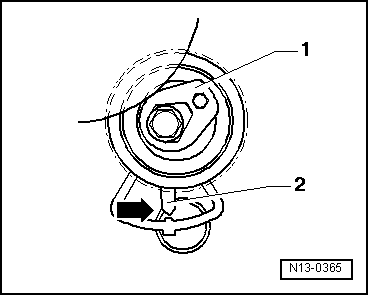

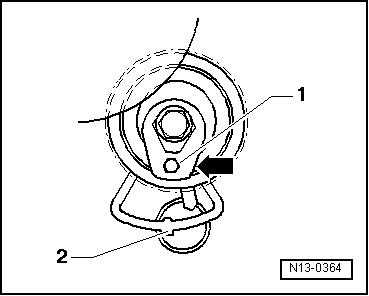

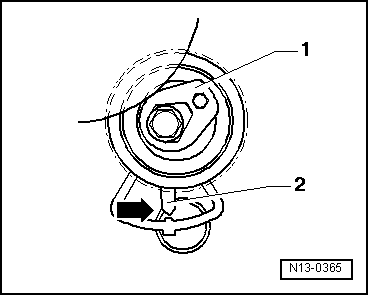

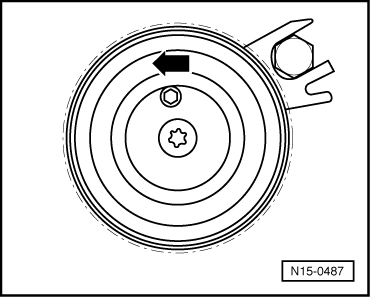

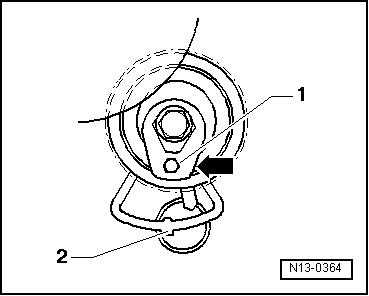

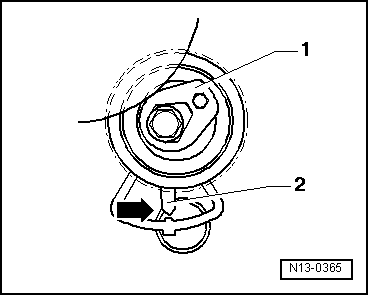

| Finally tension toothed belt by turning tensioning roller anti-clockwise using a hexagon key -1-, until the indicator -2- aligns over the lug in the base plate in the marking window -arrow-. |

| –

| Tighten clamping nut on tensioning roller. Specified torque: 20 Nm |

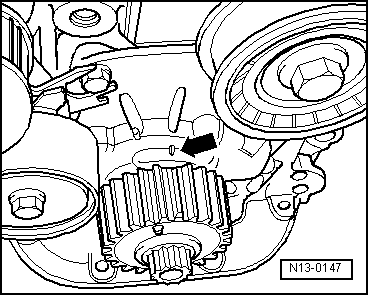

Note | The camshaft must be secured by the tool against turning until the main drive toothed belt is fitted. |

| –

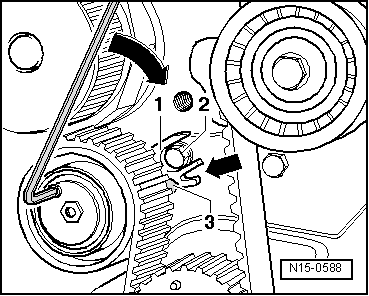

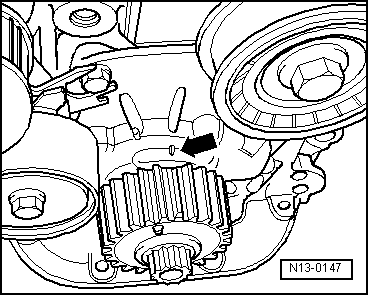

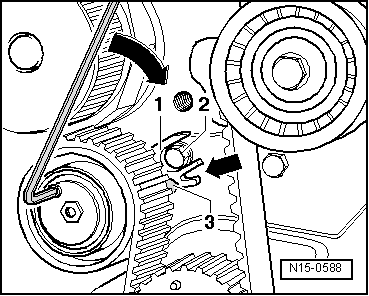

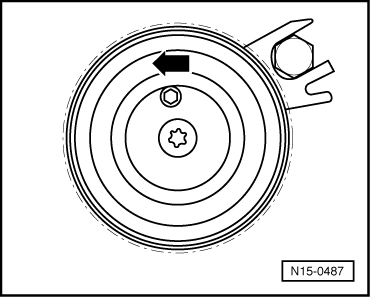

| Fit main drive toothed belt on in an anti-clockwise direction starting at water pump then over tensioning roller, crankshaft, idler roller and inlet camshaft pulley. Note direction of rotation with used belts. |

| If tensioning roller was removed beforehand, install tensioning roller as follows: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note