Polo Mk5

|

| Special tools and workshop equipment required |

| t | Torque wrench (5…50 Nm) -V.A.G 1331- |

| t | Auxiliary measuring set -V.A.G 1594C- |

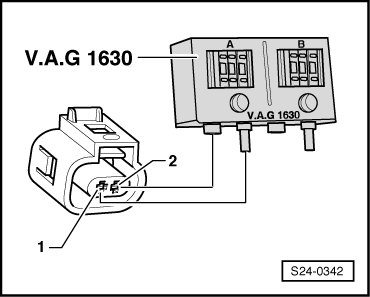

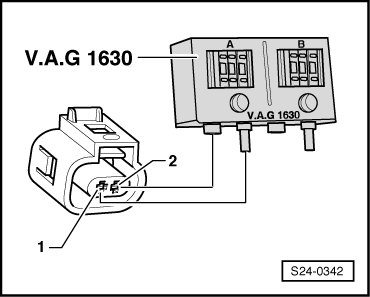

| t | Digital potentiometer -V.A.G 1630- |

| t | Measuring glass |

|

|

|

|

|

|

|

|

| Special tools and workshop equipment required |

| t | Torque wrench (5…50 Nm) -V.A.G 1331- |

| t | Auxiliary measuring set -V.A.G 1594C- |

| t | Digital potentiometer -V.A.G 1630- |

| t | Measuring glass |

|

|

|

|

|

|

|