| –

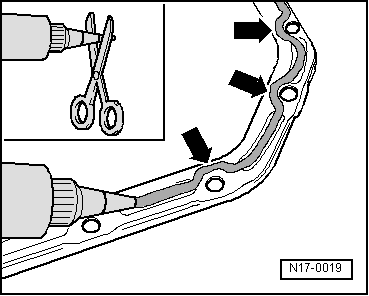

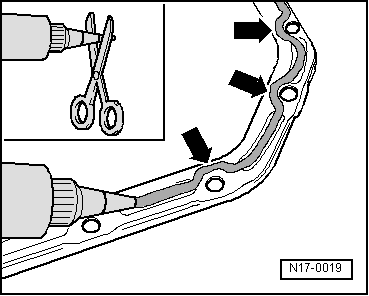

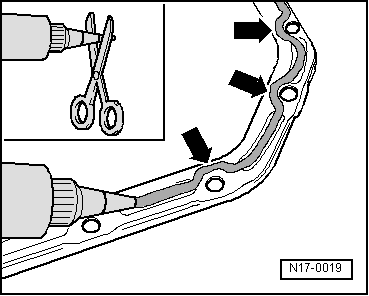

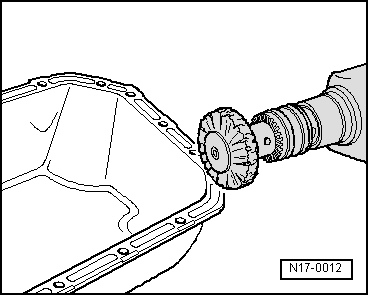

| Cut off tube nozzle at forward marking (nozzle Ø approx. 3 mm). |

| –

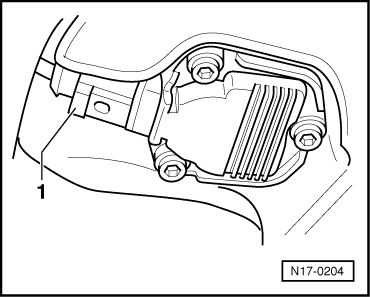

| Apply silicone sealing compound, as shown, to clean sealing surface on sump. Sealing compound bead must be: |

| t

| Run bead along inner side of bolt holes -arrows-. |

Note | The sealing compound bead must not be thicker, or excessive sealing compound will enter the sump and may block the oil suction pipe strainer. |

| –

| Install sump immediately and tighten all sump bolts lightly. |

| –

| Tighten sump bolts to 13 Nm. |

Note | Let sealing compound dry for approx. 30 minutes after installing sump. Only then fill with engine oil. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note