| –

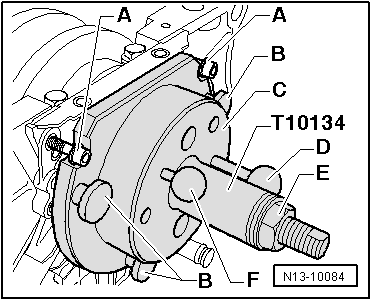

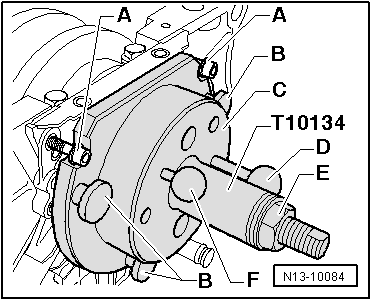

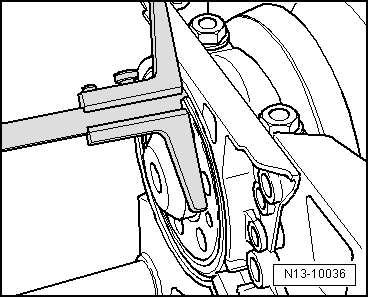

| Set vernier gauge on crankshaft flange. |

| –

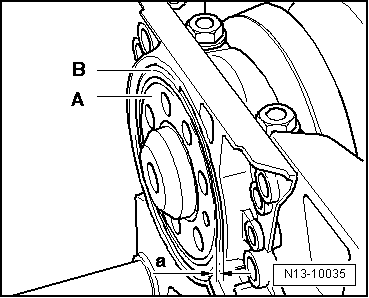

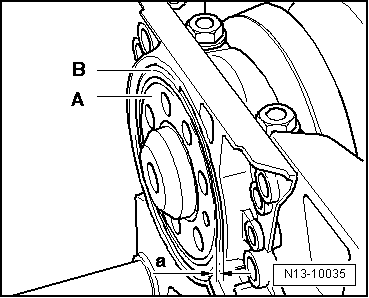

| Measure distance -a- between crankshaft flange and sender wheel. |

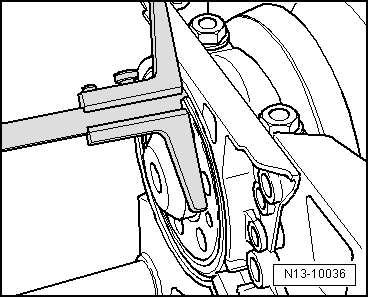

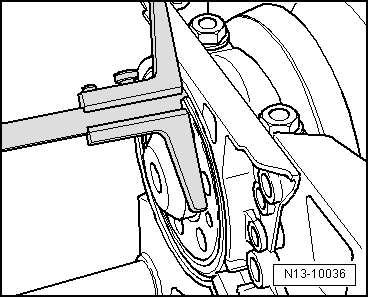

| If measurement -a- is too small: |

| If dimension -a- is attained: |

| –

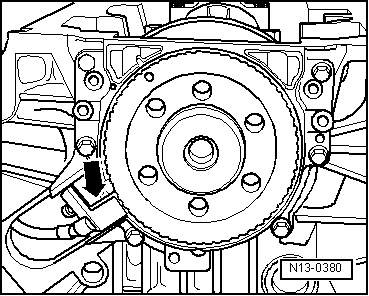

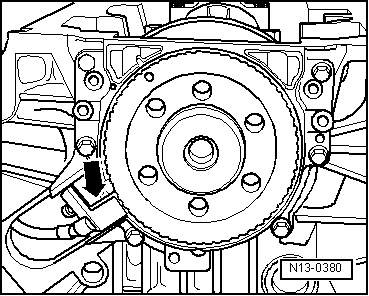

| Tighten new securing bolts for sealing flange to 12 Nm using alternate and diagonal sequence. |

|

|

|