| –

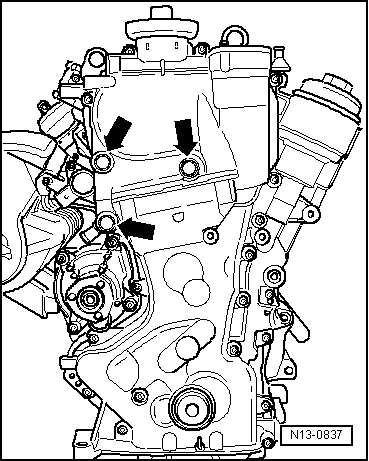

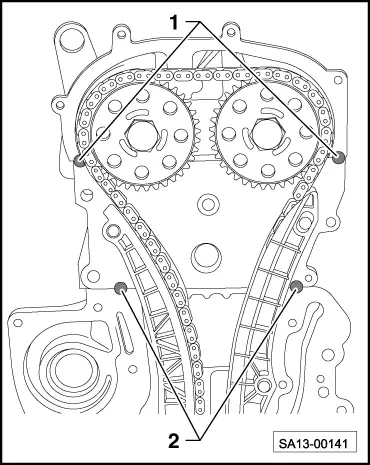

| Apply sealant D 176 501 A1 to the joints camshaft housing/cylinder head -1- and cylinder head/cylinder block -2-. |

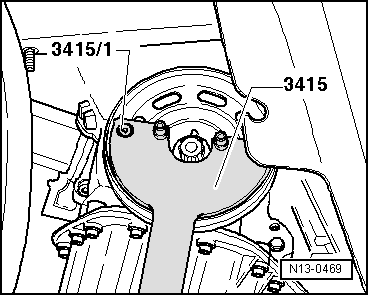

| If new repair set is used, diamond-coated disc (inner diameter 23 mm) must be first pushed onto crankshaft journal to stop. |

| Tightening procedure for poly V-belt pulley securing bolt → Chapter |

| Renew crankshaft oil seal - pulley end → Chapter |

| –

| Fit new gasket onto dowel pins. |

| –

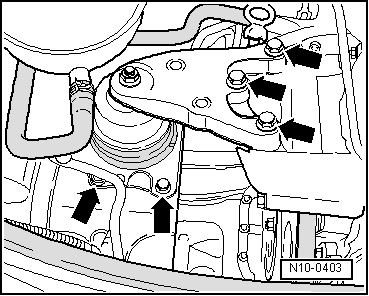

| When fitting, install two -M6x80- studs into cylinder head and cylinder block as a guide. |

| –

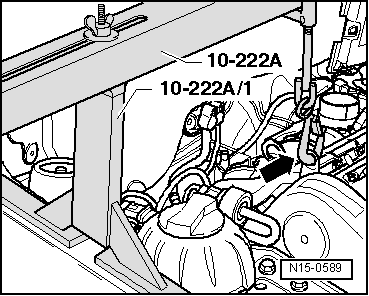

| Fit valve timing housing with crankshaft bearing bush simultaneously onto studs, dowel pins and crankshaft journal. |

| –

| Tighten valve timing housing securing bolts evenly and diagonally. |

| Ensure that camshaft housing is not canted. |

| Tightening procedure for poly V-belt pulley securing bolt → Chapter |

| Further assembly is basically the reverse of the dismantling procedure. |

|

|

|

Note

Note Note

Note Note

Note