| t

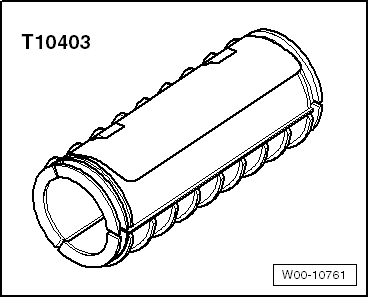

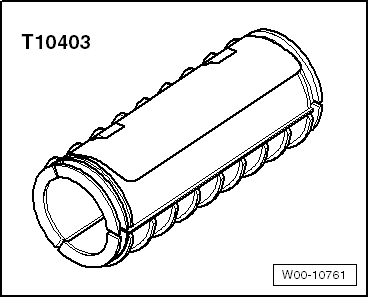

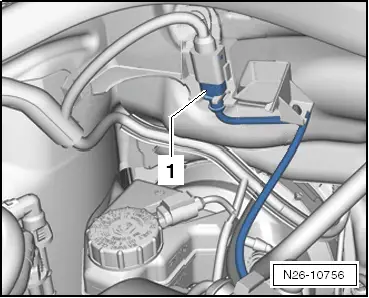

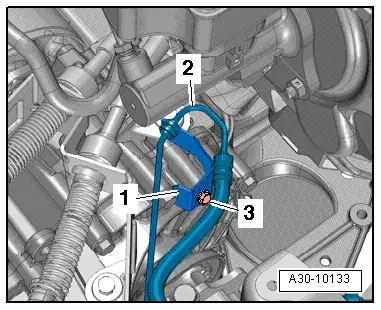

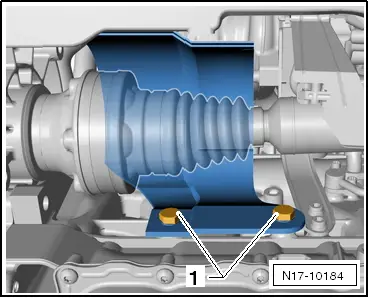

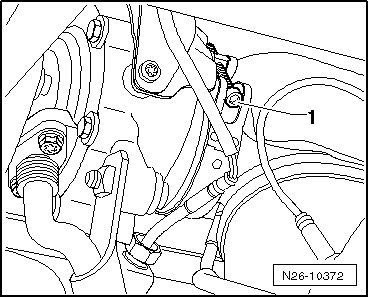

| Transportation lock -T10403- |

| t

| Engine bung set -VAS 6122- (not

shown) |

Note | t

| Before carrying out further work, disconnect battery earth

strap. Check whether a coded radio is fitted. Obtain anti-theft coding

if necessary. |

| t

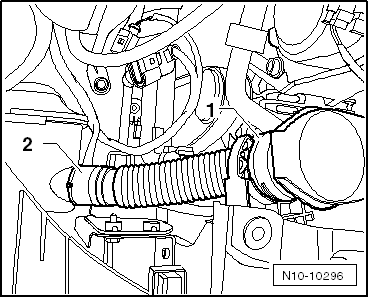

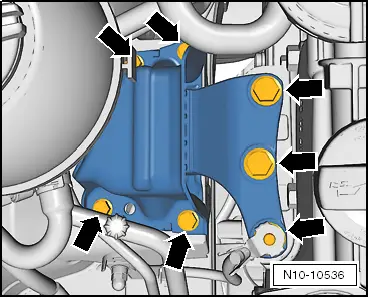

| The engine is removed forwards together with the gearbox. |

| t

| All cable ties that are opened or cut through when the engine

is removed must be renewed in the same position when the engine is

installed. |

WARNING | When doing any repair work, especially in the engine compartment,

pay attention to the following due to the cramped conditions: |

| t

| Route all the various lines and electrical wiring so that they

are in their original positions. |

| t

| e.g. for fuel, hydraulics, activated charcoal filter system,

coolant and refrigerant, brake fluid, vacuum. |

| t

| Ensure that there is sufficient clearance to all moving or

hot components. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING