| t

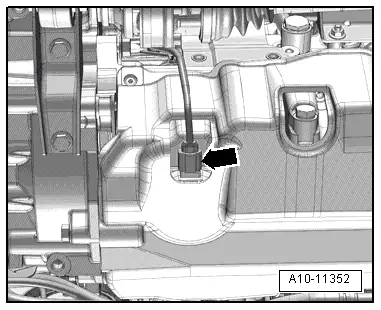

| Hand drill with plastic brush |

Note | t

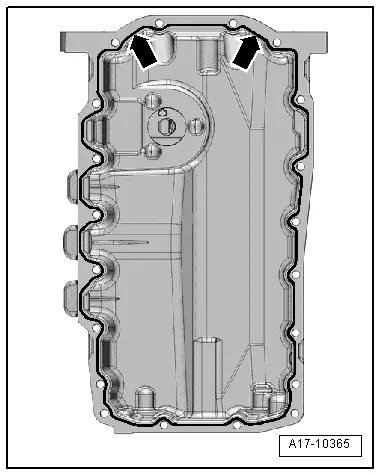

| Metal shavings or a large quantity of small metal particles found during engine repair could indicate that the crankshaft bearings or conrod bearings are damaged. To avoid any subsequent damage, you must carry out the following work following repair: |

| t

| Thoroughly clean oil channels. |

| t

| Oil capacities, oil specifications, viscosity grades → Chapter. |

| t

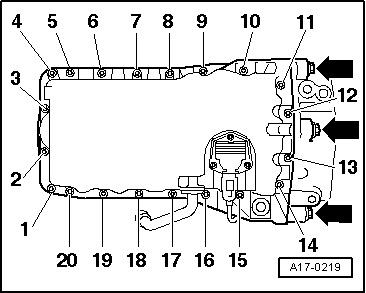

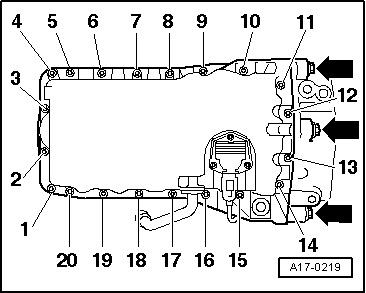

| Oil spray jet and pressure relief valve → Fig. |

| »Carry out the following work sequence« |

| –

| Place used oil collection and extraction unit -V.A.G 1782- under engine and drain engine oil. |

Note | Observe environmental regulations for disposal. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING