Polo Mk5

| Assembly overview - removing and installing flywheel (vehicles with single flywheel) |

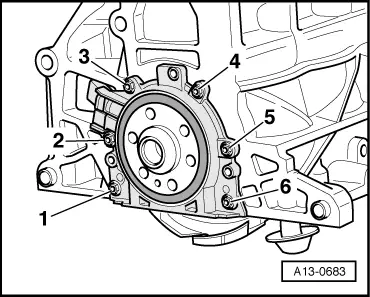

| 1 - | Bolt |

| q | Renew. |

| q | 60 Nm + 90° |

| 2 - | Flywheel |

| q | To remove and install flywheel → Power transmission; Rep. gr.34. |

| q | To remove and install flywheel, counterhold with 3067. |

| q | Assembly through offset holes only possible in one position |

| 3 - | Sender wheel |

| q | For engine speed sender -G28-. |

| q | Removing and installing → Chapter. |

| 4 - | Engine speed sender -G28- |

| q | Removing and installing → Chapter. |

| 5 - | Bolt |

| q | 4.5 Nm |

| 6 - | Dowel pin |

| q | Qty. 2. |

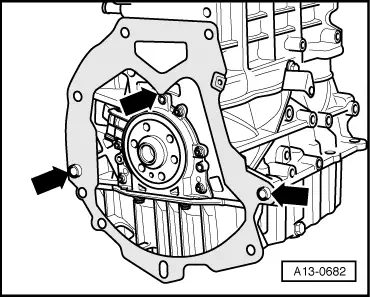

| 7 - | Intermediate plate |

| q | Do not damage or bend when assembling. |

| q | Installing → Fig.. |

| 8 - | Sealing flange with oil seal |

| q | Removing and installing → Chapter. |

| q | With sender wheel for engine speed. |

| q | Renew complete only. |

| q | Do not additionally oil or grease the oil seal sealing lip. |

| q | Before installing, remove oil residue from crankshaft journal using a clean cloth. |

| q | Use support sleeve supplied when installing. |

| 9 - | Bolt |

| q | Specified torque and tightening sequence → Fig.. |

|

|

|

|

| Stage | Bolts | Specified torque |

| 1. | -1 … 6- | screw in to contact by hand |

| 2. | -1 … 6- | in diagonal sequence and in stages; final torque 15 Nm |

Note

Note

|