Polo Mk5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

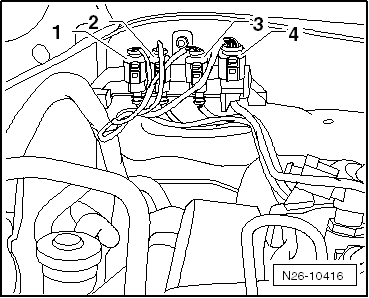

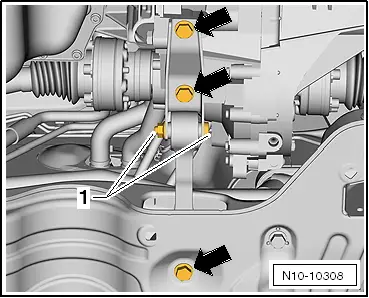

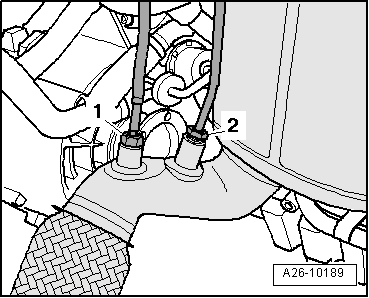

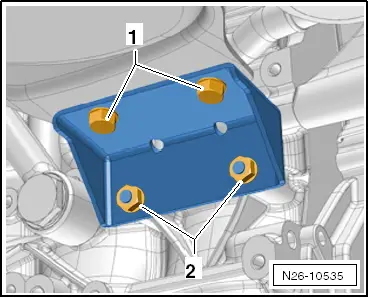

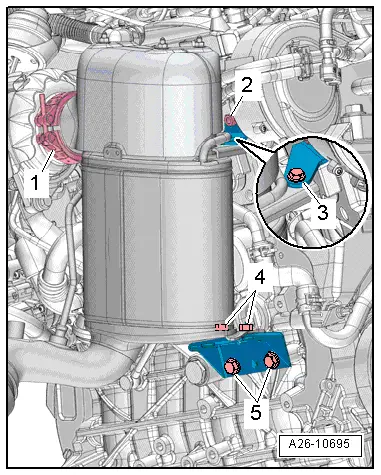

| 1. | position particulate filter on turbocharger and secure clip -1- loosely | |||

| 2. | screw bolts and nuts -2 … 5- in loosely by hand

| |||

| 3. | tighten clip -1- | |||

| 4. | tighten nuts and bolts -2- and -5- | |||

| 5. | tighten nuts and bolts -3- and -4- | |||

|

|