| –

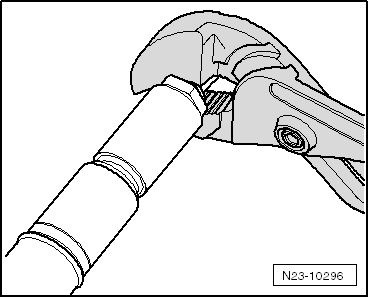

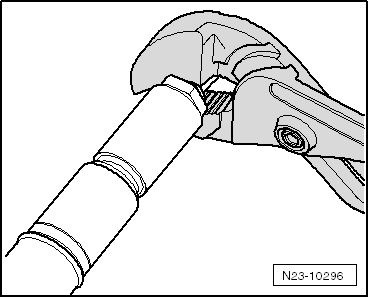

| Fit renewed clips before fitting the injector. To do this, grease lightly. |

| When a fitting a new injector, the following must be replaced: |

| Included in scope of supply. |

| t

| O-ring for injector shaft |

| t

| O-ring for injector return line |

| t

| Retaining clip for injector return |

| Continuation for used and new injectors: |

| –

| Use a plastic socket to mount new copper seal. |

| –

| Lubricate all O-rings with engine oil or assembly oil before installing. |

| –

| Fit new O-rings for injector shaft. |

| –

| Push clamping piece onto injectors, during this process pay attention to installation position. |

| –

| Carefully guide two injectors at a time into the injector bores in the cylinder head. |

| –

| Tighten bolt for clamp to a maximum of only 1 - 2 Nm at first → Item. |

| l

| Injectors must still be able to move. |

| Further assembly in reverse order of removal. |

| –

| Adapt correction values for injectors → Chapter. |

|

|

|

Note

Note

Note

Note