| –

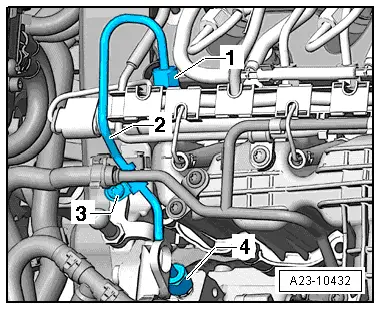

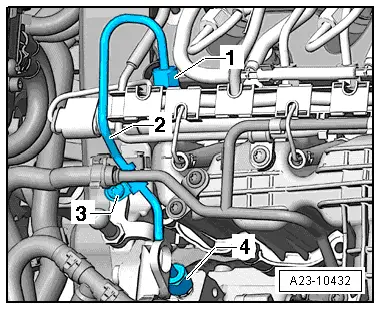

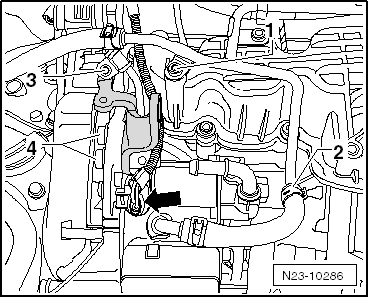

| Tighten bolt -3- for retainer for high-pressure

line. |

| t

| Specified torques: assembly overview - fuel system → Chapter. |

| t

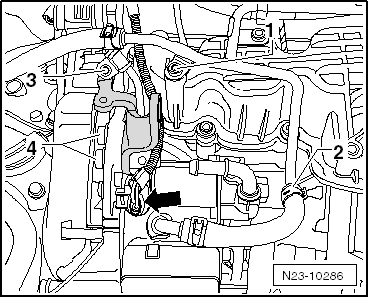

| Firmly screw lifting eye in → Item. |

| –

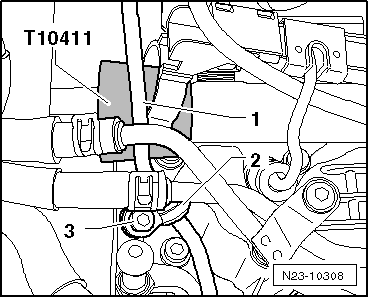

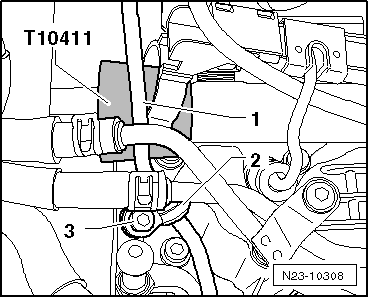

| Remove the support sleeve -T10411 -. |

| –

| Tighten high-pressure accumulator to specified torque → Item. |

| –

| Tighten bolts for clamps to final tightening torque → Item. |

| –

| Reconnect connector to fuel pressure sender -G247-. |

| –

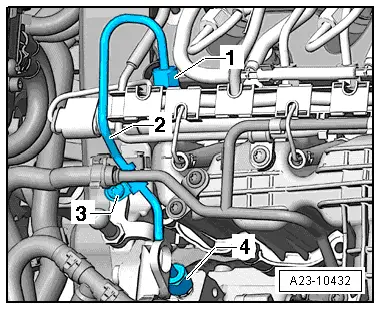

| Press return line connections carefully onto injectors (check

seal for damage before connecting return line). You should hear them

click into place. |

| –

| Engage pressure retention valve in retainer provided on

the cylinder head cover. |

Note | t

| „Reading / adapting injector correction values“. |

| –

| Run engine at idling speed for several minutes and then

switch off. |

| –

| Check the complete fuel system and return line connections

for leaks. |

| Renew the affected component if leakage still occurs after

tightening to the correct torque. |

| –

| Then test drive the vehicle, accelerating to full throttle

at least once. |

| –

| Then check high-pressure part of fuel system again for leakage. |

Note |

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note