Polo Mk5

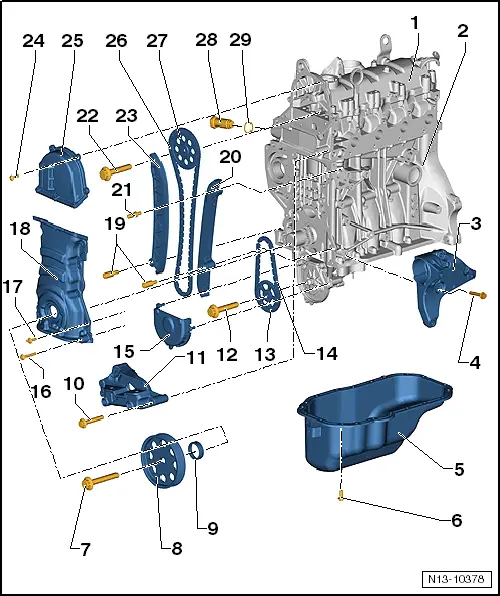

| Assembly overview - timing chain |

| 1 - | Cylinder head with cylinder head cover |

| q | Remove and install cylinder head → Chapter. |

| q | Remove and install cylinder head cover → Chapter. |

| q | Sealing surface must not be reworked. |

| q | With integrated camshaft bearings. |

| q | Remove sealant residue. |

Caution

Caution

|

| q | Apply sealant D 189 500 A1 and D 154 103 A1 before positioning. |

| q | When installing, insert vertically from above so that dowel pins fit into holes in cylinder head |

| 2 - | Cylinder block |

Caution

Caution

|

| q | Dismantle and assemble cylinder block → Chapter. |

| q | Dismantle and assemble pistons and conrods → Chapter |

| 3 - | Bottom ancillary bracket |

| q | For tensioning element and air conditioner compressor. |

| q | Remove and install → Chapter |

| q | Remove and install top ancillary bracket → Chapter |

| 4 - | 25 Nm |

| 5 - | Oil sump |

| q | Remove and install → Chapter |

| q | Clean sealing surface before fitting. |

| q | Install with silicone sealant D 176 600 A1. |

| 6 - | 13 Nm |

| 7 - | 150 Nm + turn 180° further. |

| q | Remove and install crankshaft pulley → Chapter. |

| q | Renew. |

| q | Contact surface for securing bolt must be free of oil and grease. |

| q | Oil threads before inserting. |

| q | Secure belt pulley against turning with counterhold tool -3415-. |

| q | The turning further angle can be measured with a commercial protractor. |

| 8 - | Belt pulley |

| q | With diamond coated washer (clipped onto belt pulley) |

| q | Observe tightening procedure → Chapter. |

| q | Contact surfaces must be free of oil and grease. |

| q | Secure belt pulley against turning with counterhold tool -3415-. |

| q | Remove and install poly V-belt → Chapter. |

| 9 - | Seal |

| q | Renew. |

| q | Remove and install → Chapter |

| 10 - | 50 Nm |

| 11 - | Engine support |

| q | For assembly mounting |

| 12 - | 20 Nm + turn 90° further |

| q | Renew. |

| 13 - | Chain sprocket |

| q | For oil pump drive. |

| q | Contact surfaces must be free of oil and grease. |

| q | Lock sprocket using counterhold -T10172-. |

| 14 - | Oil pump drive chain |

| q | Before removing, mark direction of rotation (installation position). |

| 15 - | Cover |

| 16 - | 5 Nm + turn 30° further |

| q | Bolt: M6x40 |

| q | Tighten with torque wrench -VAS 6583-. |

| 17 - | 5 Nm + turn 30° further |

| q | Bolt: M6x20 |

| q | Tighten with torque wrench -VAS 6583-. |

| 18 - | Bottom valve timing housing |

| q | Remove and install → Chapter |

| q | Install with sealant D 176 501 A1 |

| 19 - | Bearing mounting |

| q | Specified torque. 18 Nm |

| 20 - | Guide rail |

| q | For timing chain. |

| 21 - | Bearing mounting |

| q | Specified torque. 18 Nm |

| 22 - | 50 Nm + turn 90° further |

| q | Renew. |

| 23 - | Tensioning plate |

| q | For timing chain. |

| 24 - | 8 Nm |

Caution

Caution

|

| 25 - | Top valve timing housing |

| q | Install with sealant D 176 501 A1 |

Caution

Caution

|

| 26 - | Timing chain |

Note

Note| t | Only in vehicles manufactured from June 2011: |

| t | If timing chain has been removed and installed or renewed, erase learnt values and adapt engine control unit → Vehicle diagnostic tester„Guided Functions“. |

| q | Remove and install → Chapter |

| 27 - | Chain sprocket |

| q | Lock sprocket using counterhold -T10172-. |

| 28 - | Chain tensioner |

| q | For timing chain. |

| q | Specified torque: 60 Nm |

| 29 - | Seal |

| q | Renew. |