| l

| The pistons must not be positioned at TDC. |

Note | t

| Do not remove new cylinder head gasket from its packing until immediately before installing. |

| t

| Handle new gasket with extreme care. Damage will cause leakage. |

| t

| The strainer for oil circuit must be installed in cylinder head. |

| –

| Place clean cloths in cylinders so that no dirt or emery cloth particles can get in between cylinder wall and piston. |

| –

| Now carefully clean sealing surfaces of cylinder head and cylinder block. Ensure thereby that surfaces are not scored or scratched (if abrasive paper is used, grade must not be less than 100). |

| –

| Carefully remove metal particles, emery residue and cloths. |

| –

| Set No. 1 cylinder piston to top dead centre and then turn crankshaft back slightly. |

| –

| Fit new cylinder head gasket. Lettering (Part No.) must be readable. |

| –

| Fit cylinder head. When doing this, observe centring pins in cylinder block. |

| –

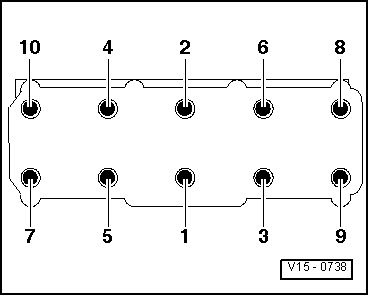

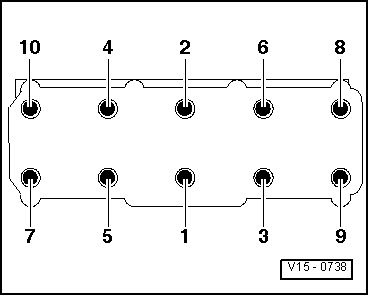

| Insert new cylinder head bolts and tighten hand-tight. |

|

|

|