| –

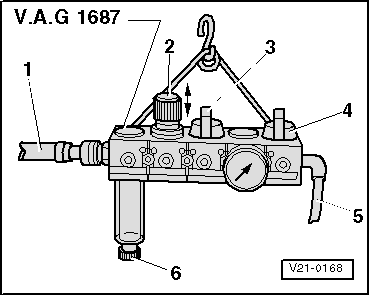

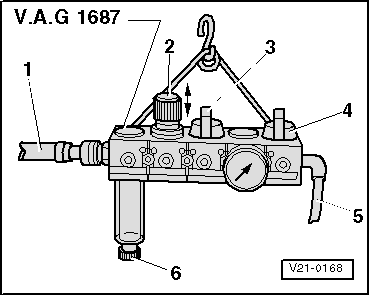

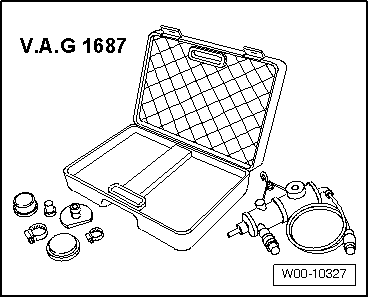

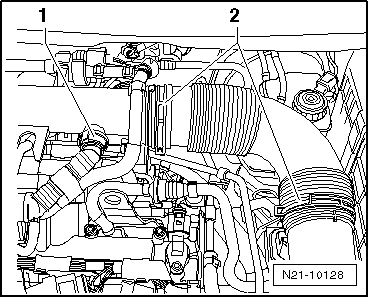

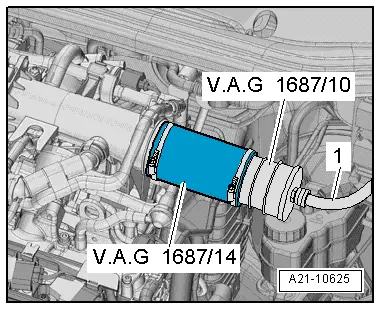

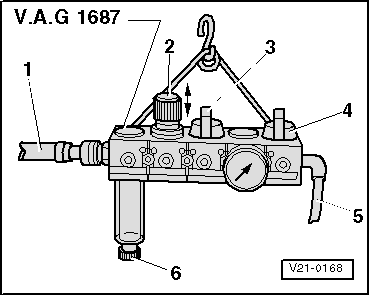

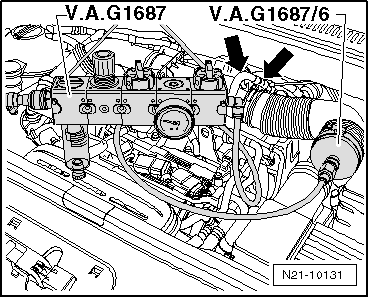

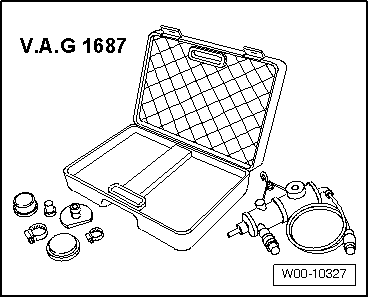

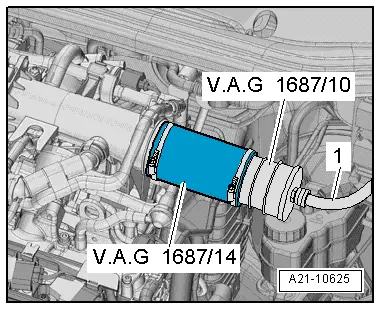

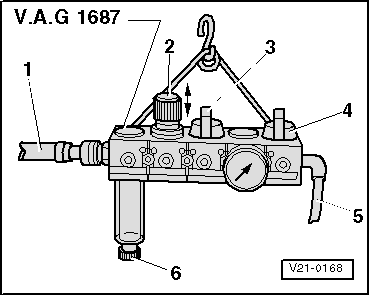

| Connect pressure hose -1- (compressed air supply) to charge air system tester -V.A.G 1687-. |

Note | If there is water in the sight glass, drain at water drain screw -6-. |

| –

| Adjust pressure to 0.5 bar with pressure regulating valve -2-. |

Caution | The pressure must not exceed 0.5 bar! If the pressure is too high this can cause damage to the engine. |

|

| –

| Open valve -4- and wait until the test circuit is filled. If necessary readjust pressure to 0.5 bar. |

| –

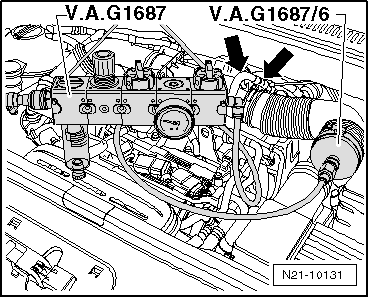

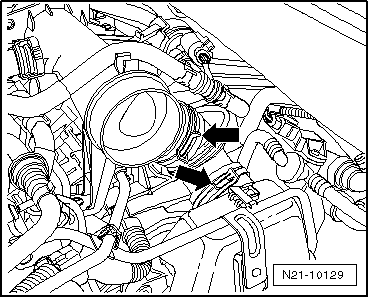

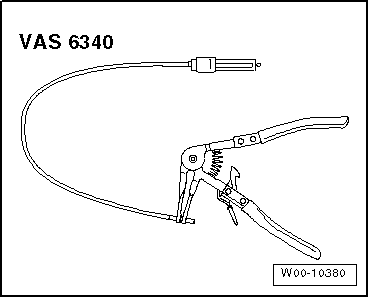

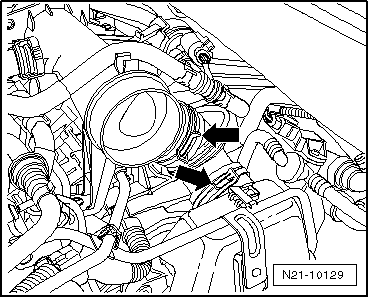

| Check the charge air system for leaks by hearing, touching, with commercially available leak detector spray or using ultrasonic tester -V.A.G 1842-. |

Note |

|

|

Note

Note Note

Note

Note

Note Note

Note