Polo Mk5

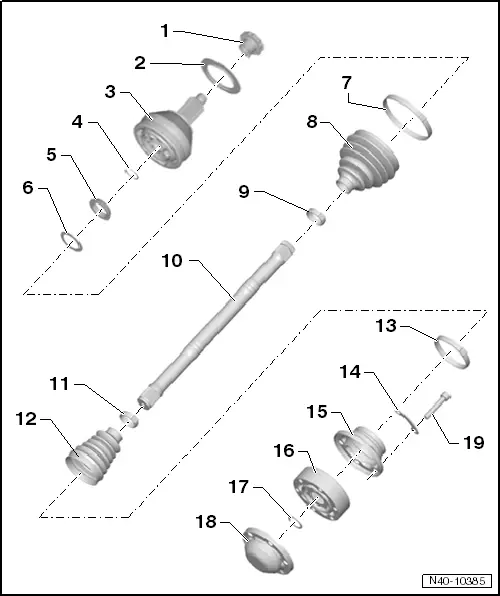

| Assembly overview - drive shaft with VL107 constant velocity joint |

| 1 - | Twelve-point nut |

| q | Self-locking. |

| q | 50 Nm and turn 45° further. |

| q | Always renew after removing. |

| q | Remove any corrosion on the thread of the outer joint before the nut is screwed on. |

| 2 - | Deflector ring |

| q | Ensure deflector ring is seated correctly before installing drive shaft → Anchor. |

| 3 - | Outer constant velocity joint |

| q | Renew only as complete unit |

| q | Removing → Anchor |

| q | Installing: drive onto shaft as far as stop using plastic hammer |

| q | Checking → Chapter. |

| 4 - | Retaining ring |

| q | Always renew after removing. |

| q | Insert in groove in shaft |

| 5 - | Spacer ring |

| q | Installation position → Fig.. |

| 6 - | Dished spring |

| q | Installation position → Fig.. |

| 7 - | Clamp |

| q | Always renew after removing. |

| q | Various versions. |

| q | Allocation → Electronic parts catalogue “ETKA”. |

| q | Tensioning, variant 1 → Fig.. |

| q | Tensioning, variant 2 → Fig.. |

| 8 - | Boot |

| q | Check for splits and chafing. |

| q | Material: Hytrel (polyester elastomer). |

| 9 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 10 - | Drive shaft |

| 11 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 12 - | Boot for constant velocity joint |

| q | Material: Hytrel (polyester elastomer). |

| q | Without breather hole. |

| q | Check for splits and chafing. |

| q | Drive off constant velocity joint with a drift. |

| q | Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing. |

| 13 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 14 - | Locking plate |

| 15 - | Cap |

| q | Drive off carefully with drift |

| q | Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing. |

| q | Adhesive surface must be free of oil and grease! |

| 16 - | Inner constant velocity joint |

| q | Renew only as complete unit |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| q | Checking → Chapter. |

| 17 - | Retaining ring |

| 18 - | Cover |

| q | Always renew after removing. |

| q | Pressing off → Fig. |

| 19 - | Multi-point socket head bolt |

| q | Initially tighten diagonally to 10 Nm |

| q | M10 x 52; 70 Nm. |

| q | Always renew bolts after removing |