| –

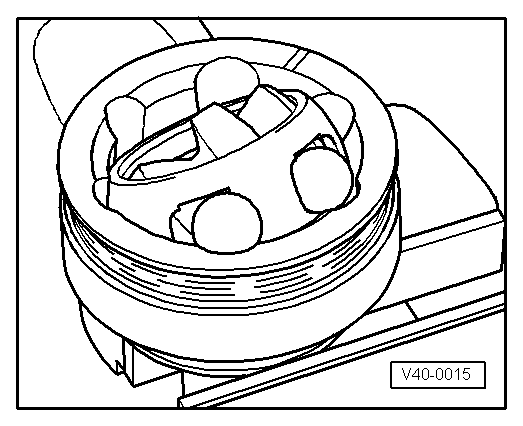

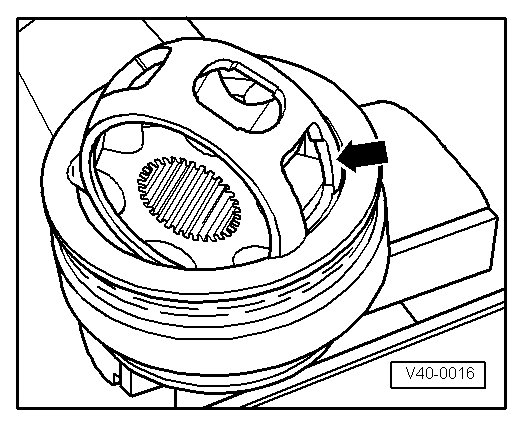

| Swing segment of hub into square cage window. |

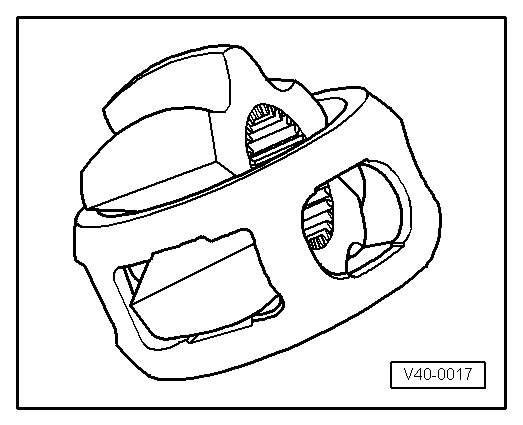

| The six balls for each joint belong to a tolerance group. Check stub axle, hub, cage and balls for small indentations (pitting) and traces of seizing. |

| Excessive circumferential backlash in the joint is noticeable during load change jolts. In this case the joint must be replaced. Smoothing and traces of wear of the balls are no reason to change the joint. |

| –

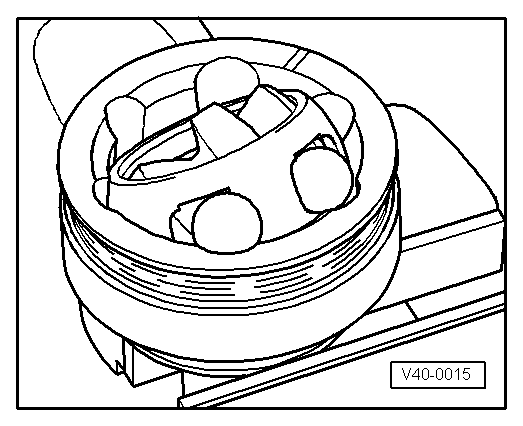

| Pack half the total quantity of grease into the joint body. |

| –

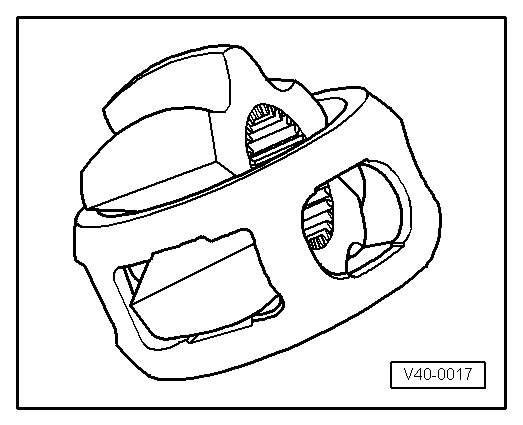

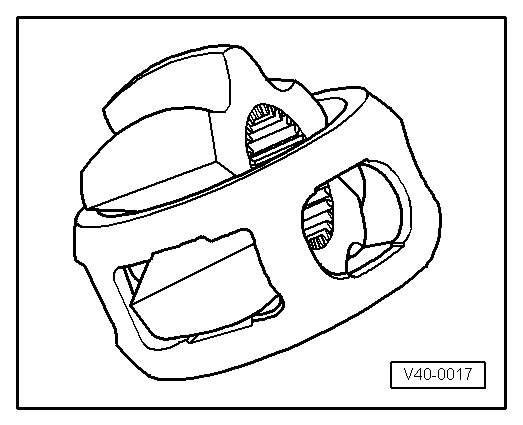

| Fit cage with hub into joint body. |

| –

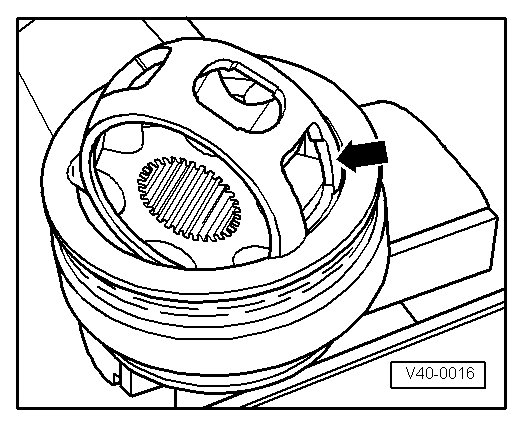

| Press in opposing balls one after the other; the original position of the hub relative to the cage and joint body must be restored. |

| –

| Fit new retaining ring into hub. |

| –

| Distribute remaining grease in boot. |

|

|

|