| –

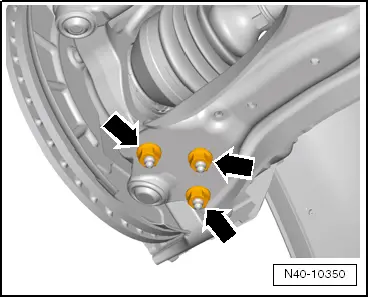

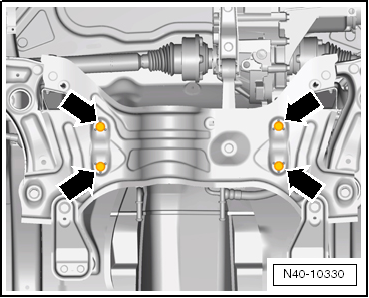

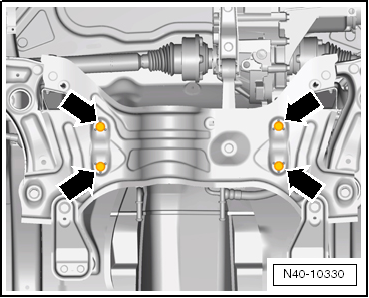

| Remove steering box bolts -arrows- from subframe. |

| –

| Lower subframe using engine and gearbox jack -V.A.G 1383 A-. |

| –

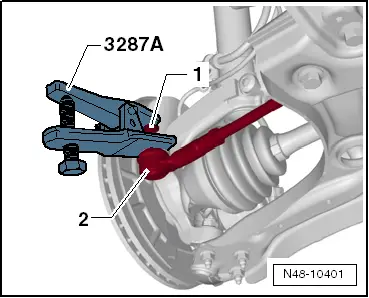

| Remove power steering box to rear. |

| t

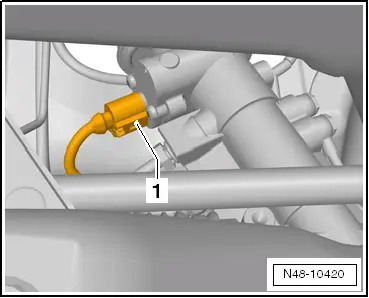

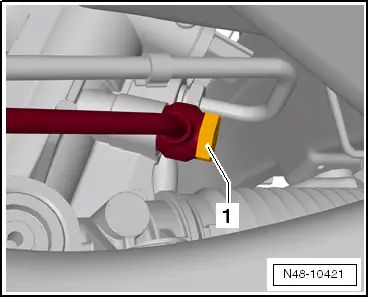

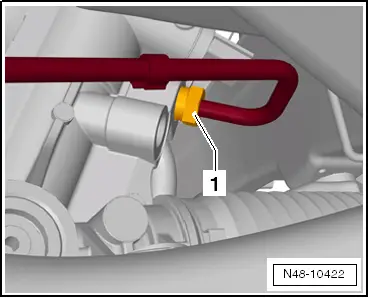

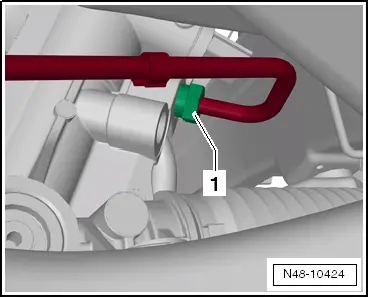

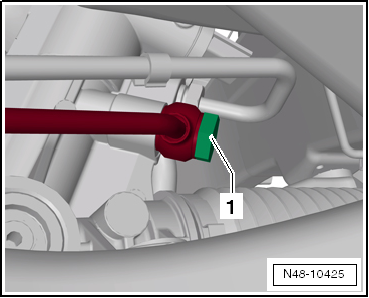

| Use new sealing rings for hose/line connections. |

| t

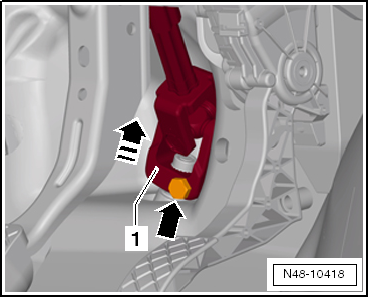

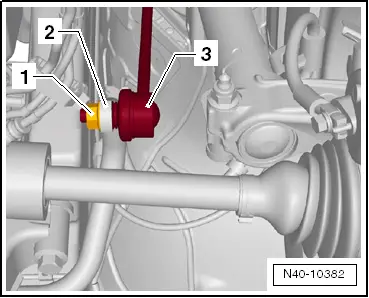

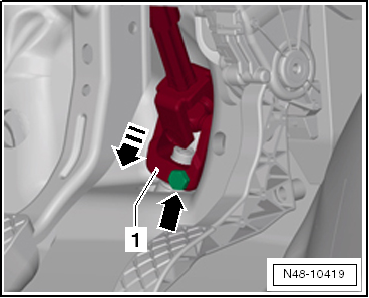

| Coat seal on steering box with suitable lubricant, e.g. soft soap, before installing steering box. |

| t

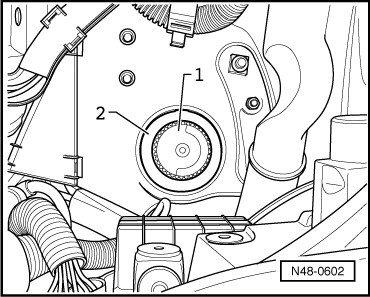

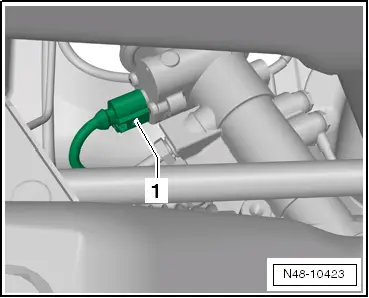

| After fitting the steering box to the drive shaft ensure that the seal is not kinked against the assembly plate on the steering box. The opening to the footwell must seal correctly. Otherwise, this can result in water leaks and/or noise. |

| t

| Ensure sealing surfaces are clean. |

| t

| When renewing the power steering box also install new bellows on the track rods. |

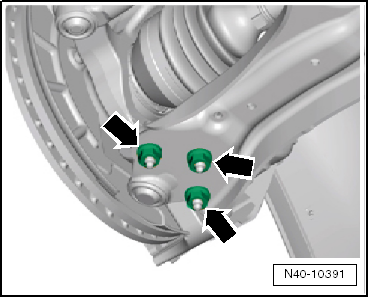

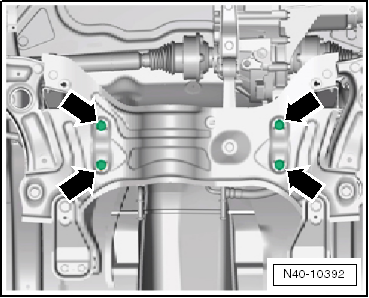

| Before inserting bolts for subframe, position power steering box on subframe and insert power steering box bolts. |

|

|

|