| t

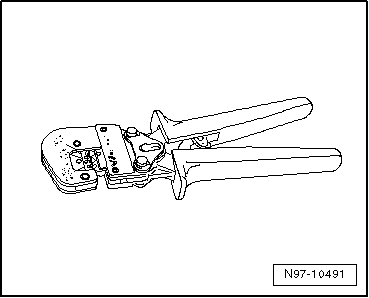

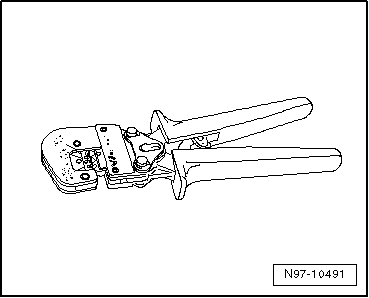

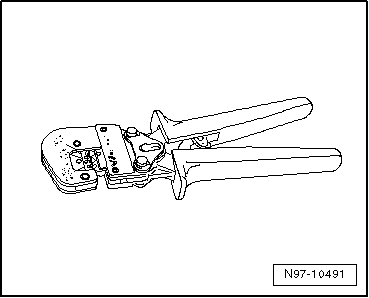

| Head adapter 0.35 mm² - 2.5 mm² -VAS 1978/1-1- |

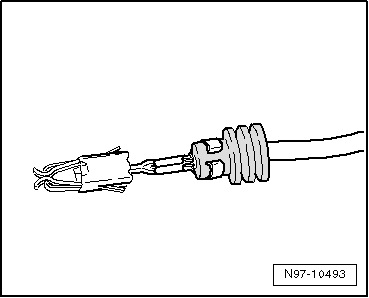

| For repairs to wiring with cross sections up to 0.35 mm2, it is essential that contacts are crimped on using crimping pliers for JPT contacts -VAS 1978/9A- or crimping pliers (base tool) -VAS 1978/1-2- with attached head adapter for JPT contacts -VAS 1978/9-1-. Due to the low current strength of these wires in the micro and thousandths range, incorrectly crimped contacts cause electrical resistances and result in faults or failure in the respective system. The most common applications of these contacts are: |

| With the use of crimping pliers for JPT contacts -VAS 1978/9A- or crimping pliers (base tool) -VAS 1978/1-2- with attached head adapter for JPT contacts -VAS 1978/9-1-, the correct connection between crimp contact, wire and single wire seal is assured. The tool is only to be used for the application described. |

Note | Crimped to the repair wiring are normal contacts and gold-plated contacts. The repair contact must always be the same type as the contact installed in the factory. |

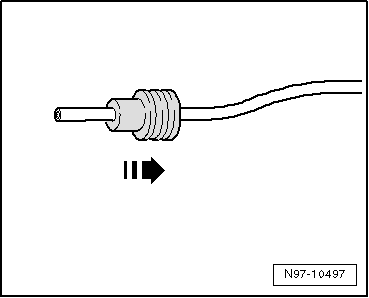

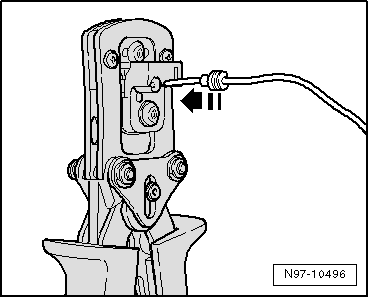

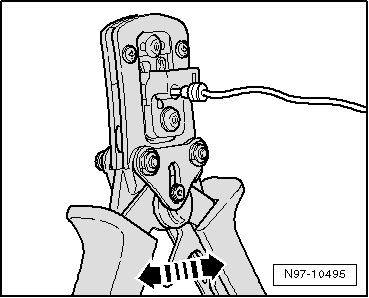

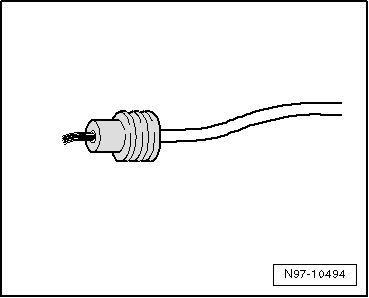

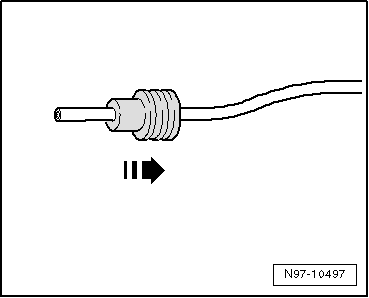

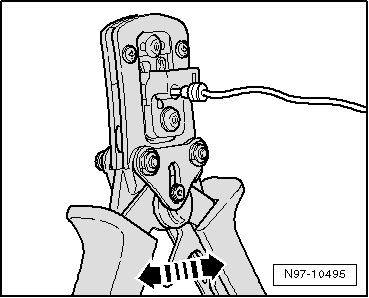

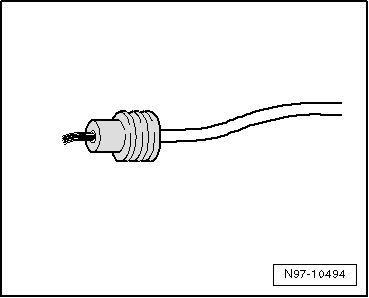

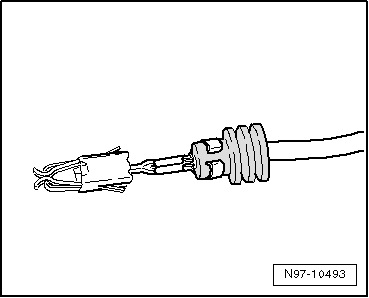

| Crimping on new contact with single wire seal |

| –

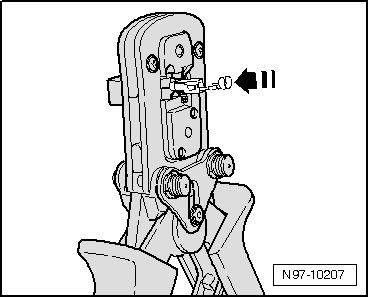

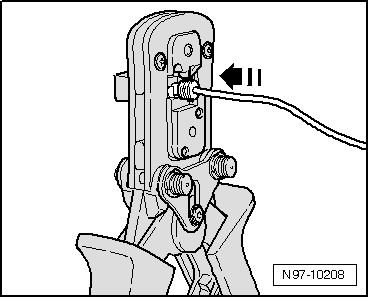

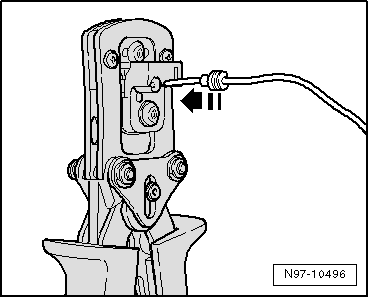

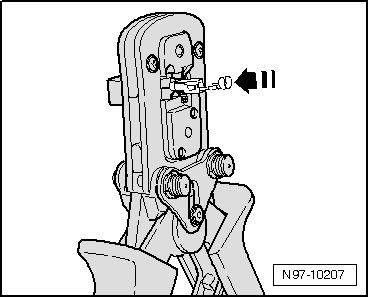

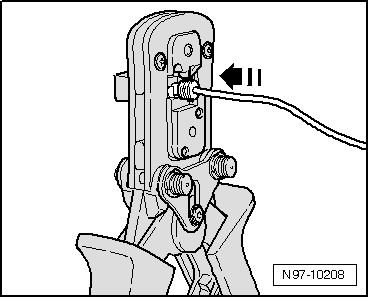

| Insert head adapter for JPT contacts -VAS 1978/9-1- in crimping pliers (base tool) -VAS 1978/1-2- → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note