| t

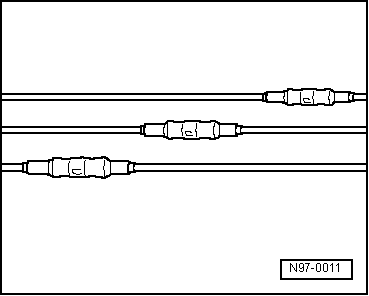

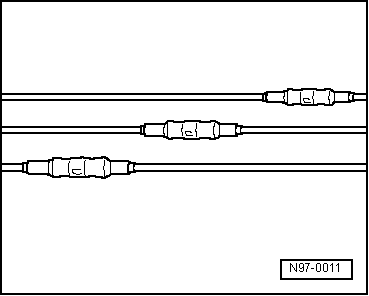

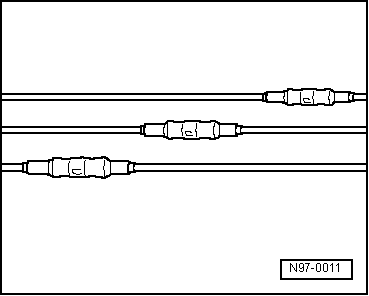

| Ensure that, where several wires have to be repaired, the crimp connectors are not directly adjacent to each other. To prevent the circumference of the wiring harness from becoming to great, position the crimp connectors so they are offset slightly. |

| t

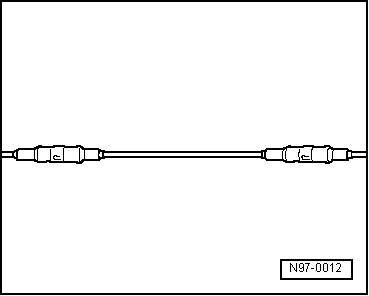

| If the repair position was already wrapped, this section has to be wrapped again with yellow insulation tape once the repair has been carried out. |

| t

| Attach the repaired wiring harness with a cable tie, if necessary, to prevent it from generating noise when the vehicle is in motion. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note