V70R L5-2.5L Turbo VIN 52 B5254T4 (2007)

Caution! Tighten to the correct torque. If the knock sensor is over-tightened it may deform. If it is too loose it may disrupt the function of the

sensor.

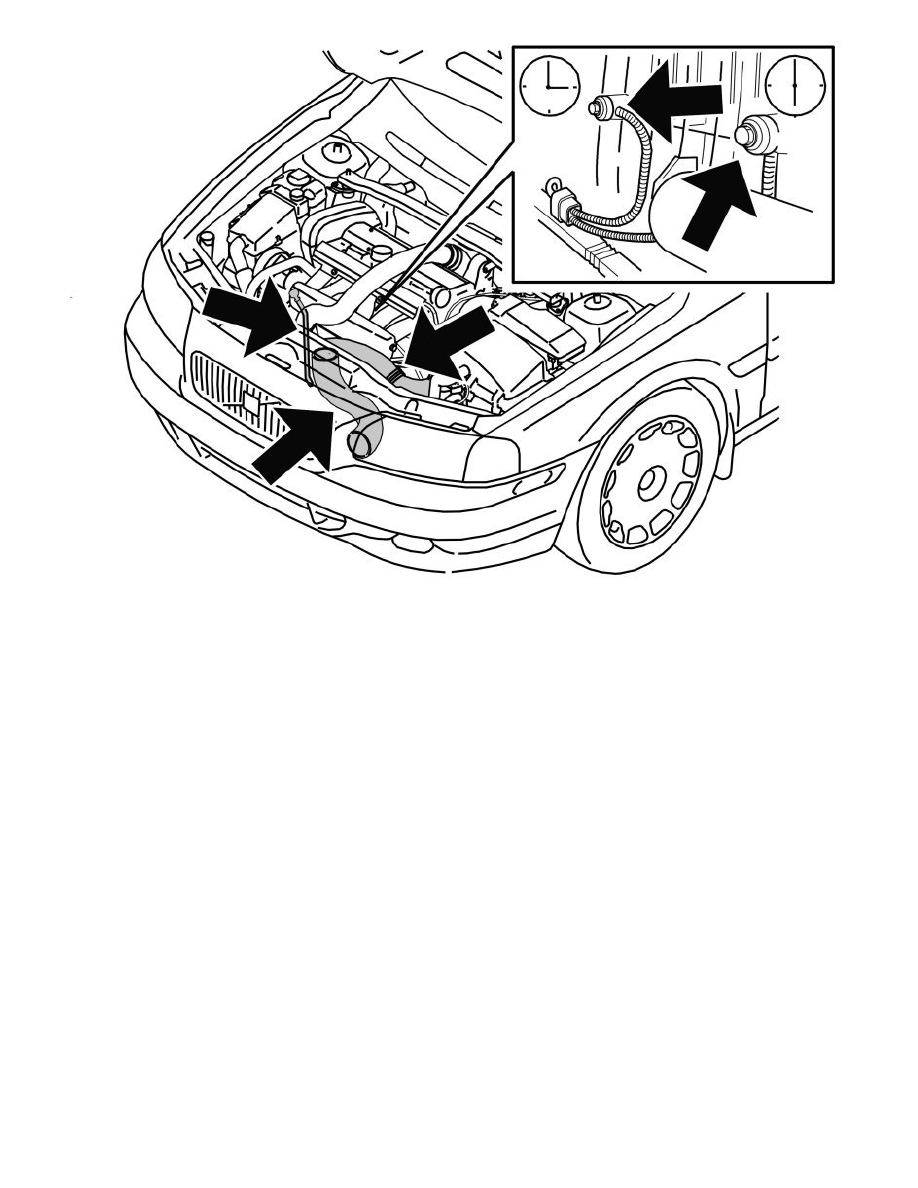

Install the new sensors with the screws in the cylinder block.

Route the cables on the outside of the starter motor bracket.

Align the sensors (looking from the front). The cable from the sensor at cylinder 3 = 3 o'clock and from the sensor for cylinder 5 = 6 o'clock.

Tighten the knock sensors. See Tightening torque See: Engine, Cooling and Exhaust/Engine/Specifications/Tightening Torque.

Press the knock sensor (KS) connectors together. Check that the wiring is in the correct position. Use a clamp if necessary.

Install the intake manifold. See Intake pipe/gasket, replacement See: Engine, Cooling and Exhaust/Engine/Intake Manifold/Service and Repair.

Connect the battery lead. See Battery, disconnecting See: Starting and Charging/Battery/Service and Repair/Procedures/Battery, Disconnecting.